05-10-2014, 06:29 PM

The area's inside the red boxes is where things were rusted up. I had to take the shaft to the wire wheel on the bench grinder to get the majority of the rust off before I could disassemble the motor. The fan blades and end bell latch springs I had to clean off in the bead blast cabinet. They have some minor pitting showing now. They used to be bright shiny steel, but I applied some cold gun blue to try and give them some rust protection in the future.

The front bearing was covered in a metallic dust/grit slurry from all the grinding and sanding operations during use, although I did blow things out from time to time with compressed air. After I got the bearings off of the shaft I popped the metal shields off of the front one and washed it out to check out the damage. No more crunchy noises when spinning the outer race, but it does have a bit of "slop" now. Without the shields it would never survive again anyway. I also spun the armature in the lathe to clean up the commutator a little and to polish the shaft up a bit. When I was doing that I noticed that the fan blades were wobbling pretty badly. Hmmmm, that's not good...

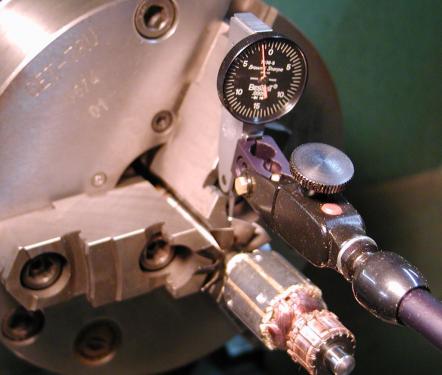

So to restore the balance and remove vibration I set up a DTI and carefully started bending the fan blades to get them aligned again. Got them all to within .005" and called it good enough. Just waiting on the new bearings now....

The front bearing was covered in a metallic dust/grit slurry from all the grinding and sanding operations during use, although I did blow things out from time to time with compressed air. After I got the bearings off of the shaft I popped the metal shields off of the front one and washed it out to check out the damage. No more crunchy noises when spinning the outer race, but it does have a bit of "slop" now. Without the shields it would never survive again anyway. I also spun the armature in the lathe to clean up the commutator a little and to polish the shaft up a bit. When I was doing that I noticed that the fan blades were wobbling pretty badly. Hmmmm, that's not good...

So to restore the balance and remove vibration I set up a DTI and carefully started bending the fan blades to get them aligned again. Got them all to within .005" and called it good enough. Just waiting on the new bearings now....

Willie