01-02-2014, 11:45 PM

No shop work yesterday. I needed to design a bunch of toolholders so that I knew the best way to make up the clamping mechanism.

Today, I got to work on the toolpost. First job was to cut the slot where the clamp would go. I love the power of a big horizontal. That's a 3/4" x 6" cutter. I chickened out and cut it in two 1/2" deep steps, instead of the whole depth at once. I'm sure it could have done it, but a slip at this stage would kill the whole project.

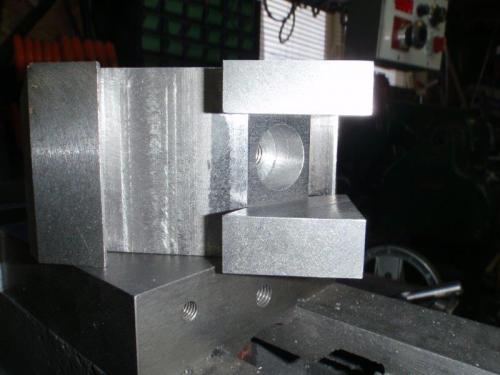

The finished slot.

Now the clamp itself. I started with a slice of 2" square HRS, squared up on the U2. Mounted in the four-jaw To turn the underside.

Lathe work done. Shaving the sides down for a good fit in the slot.

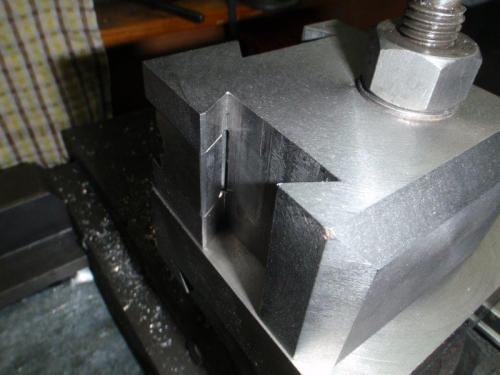

The clamp set in place and the dovetails being cut.

The toolpost is finished and ready for the toolholders.

For now, the clamp is tightened by a bolt at the tip. It's done in such a way that I can later modify it to be operated by a camlock or a bolt-operated wedge. The current bolt would then become a means of adjusting the tension.

Today, I got to work on the toolpost. First job was to cut the slot where the clamp would go. I love the power of a big horizontal. That's a 3/4" x 6" cutter. I chickened out and cut it in two 1/2" deep steps, instead of the whole depth at once. I'm sure it could have done it, but a slip at this stage would kill the whole project.

The finished slot.

Now the clamp itself. I started with a slice of 2" square HRS, squared up on the U2. Mounted in the four-jaw To turn the underside.

Lathe work done. Shaving the sides down for a good fit in the slot.

The clamp set in place and the dovetails being cut.

The toolpost is finished and ready for the toolholders.

For now, the clamp is tightened by a bolt at the tip. It's done in such a way that I can later modify it to be operated by a camlock or a bolt-operated wedge. The current bolt would then become a means of adjusting the tension.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.