10-22-2013, 02:54 PM

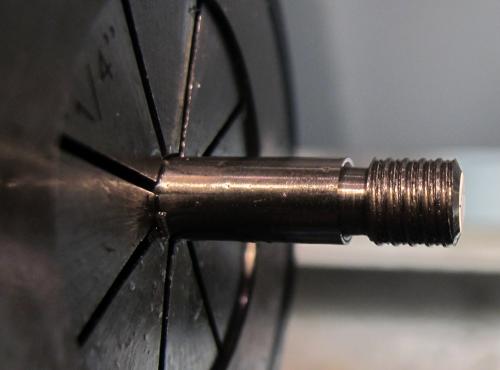

OK, this is embarrassing but I've hit a brick wall so it's time to swallow my pride. I've cut a fair number of threads with my lathe, not a ton, but a decent amount. It's been awhile since I've cut one but it's not rocket science so I'm at a loss as to why I'm having this problem. I'm cutting a 1/4-20 thread and I do the first scratch cut to check that the TPI is set up properly, and it is. Then the next pass is off a little bit even though I engaged the half nuts on the same number as the first pass. According to the chart on the thread dial housing, for a 20TPI thread I can engage the half nuts on any of the 8 numbers. I tried number 2 the first time and assumed I screwed up on engaging the half nuts so I started over and paid attention to engaging the half nuts on the number 7. Same problem. The second pass is off by a bit but it's still 20TPI. I'm perplexed.

In case it might help, the lead screw is 8TPI.

Ed

In case it might help, the lead screw is 8TPI.

Ed