04-06-2012, 07:14 PM

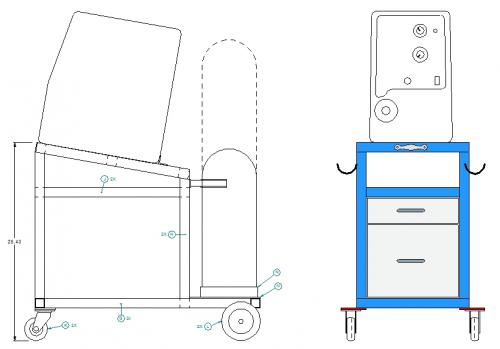

I have drawn up plans for a welding cart for my Millermatic 180 MIG welder some time ago but I suck at welding so I haven't tackled it yet. I have all of the material cut to length. See attached sketch.

I need some help on what to set my welder to for welding the the 1 1/4" square tubing which is 14 gauge, (.083") thick. In the past when I've tried to weld 14 gauge steel I just seem to blow through it too easily and give up in frustration. I'm to the point where I want to, no need to, get past this and learn what I'm doing wrong. I have both flux core and solid MIG wire along with 75/25 gas. I need help.

aametalmaster, you out there?

Ed

I need some help on what to set my welder to for welding the the 1 1/4" square tubing which is 14 gauge, (.083") thick. In the past when I've tried to weld 14 gauge steel I just seem to blow through it too easily and give up in frustration. I'm to the point where I want to, no need to, get past this and learn what I'm doing wrong. I have both flux core and solid MIG wire along with 75/25 gas. I need help.

aametalmaster, you out there?

Ed