02-06-2013, 11:04 PM

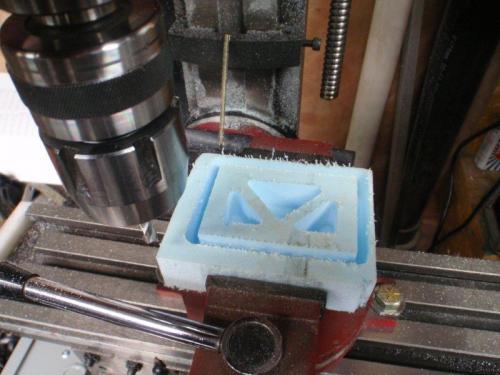

I had some setup glitches, but Steve from the other side sorted them out. I think running the first cuts in wax or foam are a good idea. Most of my cuts might end up being foam anyway - fast way to make forms for lost-foam casting.

It's nice to watch it going where you told it to go. The only oops was from doing so many dry runs before the first cut. Forgot the little step about turning on the spindle first. Another advantage of foam.

It's nice to watch it going where you told it to go. The only oops was from doing so many dry runs before the first cut. Forgot the little step about turning on the spindle first. Another advantage of foam.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.