12-30-2012, 10:51 AM

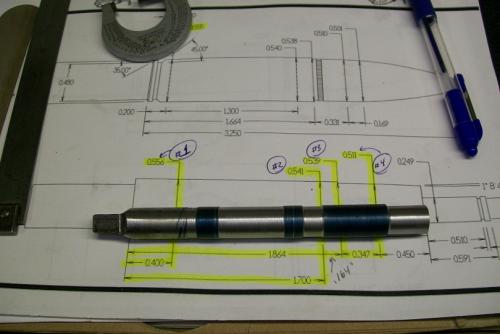

Then I marked all the diameter changes and turned the OD to within .010" at those points.

I turned all the straight tapers at this point. Then I offset the tailstock and turned the tapers.

Here it is all polished to size and ready for fluting.

Next I moved to the mill with my hex collet holder. I set it up with a stop so I could keep the flute lengths the same.

I turned all the straight tapers at this point. Then I offset the tailstock and turned the tapers.

Here it is all polished to size and ready for fluting.

Next I moved to the mill with my hex collet holder. I set it up with a stop so I could keep the flute lengths the same.

pamrick, proud to be a member of MetalworkingFun since Jul 2012.