So, since I was unable to use the 3-jaw, I removed it from the backing plate and then fabricated a quick and dirty wrench to try to remove the chuck adaptor (as I didnt have any luck with the chuck in place). Finally, with the help of a long cheater bar, it came off.

Wrench

4" spindle nose, 6tpi

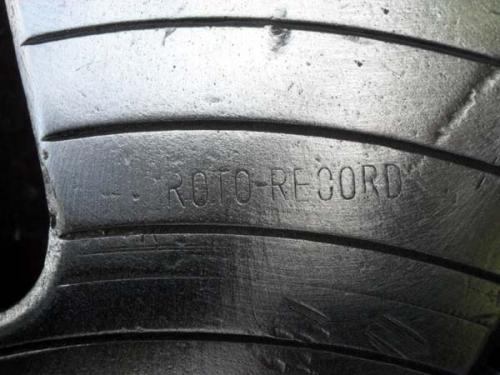

Next, I set about cleaning up the 4-jaw chuck and discovered it was made by Roto-Record in Germany. It took a while to clean up and there was that much dirt in the back that I wonder if it was buried at one point!

Ready for cleaning

1/4 done - only 3 more to go

Finished the face and can actually see a makers name!

And here I was thinking I was the only one who occasionally held a stamp the wrong way

I did say it looked like it had been buried!

All finsihed. That isn't paint either, I oiled it with Balistol

Once it was cleaned and oiled I placed the backing plate in the freezer overnight and then left the chuck in the sun all day before placing the backing plate into the recess and aligning the mating marks. Whilst I still havent made a backing pate to fit the 3-jaw, I can grip it in the 4-jaw if needed. The only problem with the 4-jaw is that I cant hold anything smaller than 2 diameter.

With the chuck off, I was able to remove the spindle from the headstock and inspect the bearings. As expected, these were white metal bearings and from what I could gather, they weren't all that bad given their age. The spindle is about 36 long and the through hole at the front is a little over 3 and a little under 3 and the end. It has a nice internal spiral running through it as well.

Spindle out of lathe and into a cradle I made to hold it

Everything but the bull gear removed and in (on) the parts cleaner

View through the spindle (from rear)

White metal bearings on a bronze shell

Wrench

4" spindle nose, 6tpi

Next, I set about cleaning up the 4-jaw chuck and discovered it was made by Roto-Record in Germany. It took a while to clean up and there was that much dirt in the back that I wonder if it was buried at one point!

Ready for cleaning

1/4 done - only 3 more to go

Finished the face and can actually see a makers name!

And here I was thinking I was the only one who occasionally held a stamp the wrong way

I did say it looked like it had been buried!

All finsihed. That isn't paint either, I oiled it with Balistol

Once it was cleaned and oiled I placed the backing plate in the freezer overnight and then left the chuck in the sun all day before placing the backing plate into the recess and aligning the mating marks. Whilst I still havent made a backing pate to fit the 3-jaw, I can grip it in the 4-jaw if needed. The only problem with the 4-jaw is that I cant hold anything smaller than 2 diameter.

With the chuck off, I was able to remove the spindle from the headstock and inspect the bearings. As expected, these were white metal bearings and from what I could gather, they weren't all that bad given their age. The spindle is about 36 long and the through hole at the front is a little over 3 and a little under 3 and the end. It has a nice internal spiral running through it as well.

Spindle out of lathe and into a cradle I made to hold it

Everything but the bull gear removed and in (on) the parts cleaner

View through the spindle (from rear)

White metal bearings on a bronze shell

Hunting American dentists since 2015.