Posts: 4,460

Threads: 184

Joined: Feb 2012

Location: Missouri, USA

The same way you would do it in a shop press - except horizontally instead of vertically. You need a ring of some sort to press the sleeve off of the body of the chuck. But the combined length would have to be able to fit in the jaw opening of the vise of course.

I tried looking at the Rohm web site to try to find some specs but it doesn't look like they provide any. Also I didn't see any models that looked like the chuck you have. Does yours have a model number on the box?

Willie

Posts: 8,859

Threads: 319

Joined: Feb 2012

Location: Arizona/Minnesota

(07-10-2021, 04:32 PM)Highpower Wrote: The same way you would do it in a shop press - except horizontally instead of vertically. You need a ring of some sort to press the sleeve off of the body of the chuck. But the combined length would have to be able to fit in the jaw opening of the vise of course.

I tried looking at the Rohm web site to try to find some specs but it doesn't look like they provide any. Also I didn't see any models that looked like the chuck you have. Does yours have a model number on the box?

The Rohm P.N. is 666573. Here's a link to it.

Rohm Chuck

I couldn't find any information on their web site that talks about disassembling their chucks.

Ed

Posts: 4,460

Threads: 184

Joined: Feb 2012

Location: Missouri, USA

I sure they don't intend for their chucks to be taken apart. There doesn't seem to be any decent information anywhere about taking them apart really. The few YouTube videos I found just show guys holding the sleeve in one hand and hammering the body out with the other.

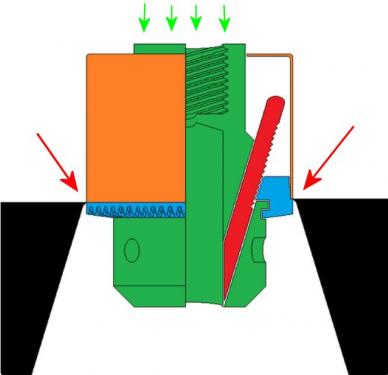

![[Image: attachment.php?aid=16913]](http://www.metalworkingfun.com/attachment.php?aid=16913)

I would find/make a piece of tubing that is a slip fit over the 'teeth' of the chuck and just catches under the fluted sleeve to push it off when you press down on the back of the chuck body.

Willie

Posts: 8,859

Threads: 319

Joined: Feb 2012

Location: Arizona/Minnesota

(07-10-2021, 11:18 PM)Highpower Wrote: I sure they don't intend for their chucks to be taken apart. There doesn't seem to be any decent information anywhere about taking them apart really. The few YouTube videos I found just show guys holding the sleeve in one hand and hammering the body out with the other. ![[Image: attachment.php?aid=16913]](http://www.metalworkingfun.com/attachment.php?aid=16913)

I would find/make a piece of tubing that is a slip fit over the 'teeth' of the chuck and just catches under the fluted sleeve to push it off when you press down on the back of the chuck body.

OK, thanks. I might try this method if I get desperate. I think I'll just go ahead and use it for a while first and see if it loosens up.

Ed

Posts: 4,460

Threads: 184

Joined: Feb 2012

Location: Missouri, USA

(07-11-2021, 10:39 AM)EdK Wrote: I think I'll just go ahead and use it for a while first and see if it loosens up.

Ed

I assumed as much. Still good to know how to get them apart if you have to. I have a small Kawasaki drill chuck (made in Japan of course) that has 3 collars on it. Two for opening & closing the chuck jaws, and a third for manually locking the jaws in place. I hope I never have to figure out how to open up

that thing!

Edit to add:

I just noticed that appears to be a Jacobs style chuck in this picture and they don't come apart the same way. The gear ring and sleeve are one piece and the body pushes out from the front, not the rear.

![[Image: attachment.php?thumbnail=17195]](http://www.metalworkingfun.com/attachment.php?thumbnail=17195)

Willie

Posts: 8,859

Threads: 319

Joined: Feb 2012

Location: Arizona/Minnesota

(07-11-2021, 02:05 PM)Highpower Wrote: ...

Edit to add:

I just noticed that appears to be a Jacobs style chuck in this picture and they don't come apart the same way. The gear ring and sleeve are one piece and the body pushes out from the front, not the rear.

![[Image: attachment.php?thumbnail=17195]](http://www.metalworkingfun.com/attachment.php?thumbnail=17195)

I think he is pushing it out from the front. The text said he pounded on the brass bushing which is sitting on the front of the chuck in the picture. Or I'm missing something, which is more likely.

Ed

Posts: 4,460

Threads: 184

Joined: Feb 2012

Location: Missouri, USA

(07-11-2021, 06:42 PM)EdK Wrote: I think he is pushing it out from the front. The text said he pounded on the brass bushing which is sitting on the front of the chuck in the picture. Or I'm missing something, which is more likely.

Ed

Right.

Jacobs style chucks push out from the front like in the picture. The sleeve and gear ring are one piece. It is a press fit over the OD. of the split nut inside that drives the jaws. But you don't have a Jacobs chuck so that won't work.

The Rohm you have is a chuck where the sleeve is a separate part from the gear ring. The sleeve has to come off the back side of your chuck not the front. Once the sleeve is off the gear ring / split nut will slide out the sides of the body. If you look closely at the OD. of the ring gear you should find two "cracks" in between the teeth 180° apart from each other. That is where the gear/nut separate into two pieces.

If you ever need a press ring to disassemble / assemble a Jacobs super chuck though, I'm your Huckleberry.

Willie

Posts: 8,859

Threads: 319

Joined: Feb 2012

Location: Arizona/Minnesota

OK, after examining my chuck in detail I see what you're saying, kind of anyway. I'm just not seeing the seams in the ring gear no matter how hard I look.

Ed

Posts: 4,460

Threads: 184

Joined: Feb 2012

Location: Missouri, USA

Wow there really aren't any good pictures of these out there on the net. The gear ring / split nut aren't cut in half per say, they are actually snapped/fractured so that when they are put back together the most you should see is what looks like a hair-line crack. Some have small grooves cut into the ring to get them to snap in a specific spot but that is usually higher up inside the sleeve and you cant see them when the sleeve is in place.

The ring half in front is sitting upside down on the table, but you can see that the sleeve on the right is what holds those pieces together when assembled.

Willie

Posts: 8,859

Threads: 319

Joined: Feb 2012

Location: Arizona/Minnesota