Posts: 535

Threads: 39

Joined: Jan 2013

Location: Kelowna, BC, Canada

I looked into getting one installed some years ago. (Just in passing - Sears had a display in the store.) Their price was $3000, even back then.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

Posts: 736

Threads: 34

Joined: Feb 2012

Location: Minneapolis, MN

The following 3 users Like arvidj's post:

EdK (05-26-2019), Highpower (05-26-2019), Vinny (05-27-2019)

05-26-2019, 07:25 AM

(This post was last modified: 05-26-2019, 07:40 AM by arvidj.)

A possible trade-off would be to get a condensing water heater.

I just installed a 95% efficient condensing boiler in my accessory building.

The advantages are the increased efficiency ... about 5% more than the non-condensing version ... and the fact that it uses cheap and easy to glue together PVC pipe for the intake and the exhaust.

The disadvantage is the extra up-front cost of the boiler.

Another disadvantage is the need for a condensate drain. If you are lucky there will be a drain close to where the combustion takes place. That is the case for the furnace in the house basement. The condensate runs down a tube and into a floor drain. If you are not lucky then there is no drain handy ... like in the accessory building ... and a condensate pump is required. It has a 1 quart or so reservoir and a level sensor. When the level is reached a small pump turns on and the condensate is pumped thru 15 feet of tubing, eventually exiting the building thru the wall. The 'condensate rabbit hole' down which I went then needs to solve the "It's Minnesota and the condensate drain may freeze where it exits the building" problem but I am now so far off topic that I may not be able to find my way back.

In my case the higher initial cost was offset over the lifetime of the boiler by the efficiency and offset immediately by the price of PVC vs stainless. A non-monetary offset to the up-front costs is the ease of installation with PVC. Not only is it easy to cut and glue compared to stainless steel but if you do it in a small enclosed space you can get a mild high from the vapors  .

Arvid

Posts: 3,798

Threads: 184

Joined: Jun 2012

Location: Farmington Hills, Michigan

My son paid $699 for his 7 GPM heater at Menards.

Tom

Posts: 642

Threads: 14

Joined: Oct 2013

Location: East Sussex, UK

The following 1 user Likes awemawson's post:

Hopefuldave (08-17-2019)

The heat exchangers of condensing boilers are the usual bugbear. They only last a few years compared to decades for earlier ones. Yet here in the UK it's hard to comply with the ECO rules without a condensing boiler.

Stupid really as it negates a lot of the energy saving when you have to factor in more frequent replacement.

It's like the old argument with the Green lobby against 'environmentally unfriendly Landrovers. As 85% of all Landrovers ever built are still on the road running, how many scrapped vehicles and environmental cost of manufacture has that saved - LOADS !

Andrew Mawson, proud to be a member of MetalworkingFun Forum since Oct 2013.

Posts: 4,460

Threads: 184

Joined: Feb 2012

Location: Missouri, USA

The following 2 users Like Highpower's post:

Dr Stan (05-26-2019), Vinny (05-27-2019)

(05-25-2019, 08:06 AM)Dr Stan Wrote: .... but the sticker shock came when I purchased the double wall stainless steel exhaust vent. Youzer!

I hear that! After having to replace the stack vent on my 'new' furnace only two years after it was installed, and again a couple of years later I had had enough and started looking for stainless steel vent pipe. The only place I could find it was McMaster and even then they didn't have any elbows or Y-fittings in stainless.

After much  and  I decided to go after the source of the problem. I invested in a combustion gas analyzer to check the furnace myself instead of paying the dimwits that installed it to come back out and check it. I found that the furnace was under fired and the stack temperature was too low, which explained the condensation buildup in the vent stack and causing it to rust out after two heating seasons. After clocking the gas meter and finding I was short on BTU's I ordered new gas nozzles one size up from the factory installed nozzles.

After cleaning the burners and replacing the nozzles I clocked the meter again and was getting the full BTU's the furnace was supposed to be getting. Adjusted the manifold pressure for best combustion results and was getting a higher stack temperature in the normal range to keep the moisture in the flue gas hot enough to go up and out the chimney instead of condensing on the inner walls of the vent pipe.

I figure that it would have cost just as much to have the HVAC knuckleheads (the one's that put a 12 cent Lowes light switch on the furnace) come out again to do the work (that they SHOULD have done after installing the furnace) as I paid for the analyzer. So essentially I got my furnace fixed and got a free tool out of the deal for the same money.

Oh, and the furnace's efficiency (80%) is now up to where it should have been all along, so my gas bill has dropped quite a bit too.

Willie

Posts: 2,328

Threads: 271

Joined: Jun 2014

Location: La Libertad, Philippines

(05-26-2019, 08:05 AM)TomG Wrote: My son paid $699 for his 7 GPM heater at Menards.

Tom

Ditto

Posts: 2,620

Threads: 100

Joined: Dec 2014

Location: Michigan

The following 5 users Like Vinny's post:

f350ca (08-07-2019), TomG (08-07-2019), EdK (08-07-2019), arvidj (08-07-2019), Highpower (08-07-2019)

I guess noone's getting any new or new to them stuff. I haven't posted in a while, been really rather busy. Bought a new (to us) camper, 28' 5th wheel, pics of that later, and it's kept me quite busy. Since it's a little heavier and hooks to the tow vehicle different than the popup, I had to do a lot of work on the truck. Some of it coming as we were trying to go on the first trip with it!

Anyway, among other stuff that's been happening, I got a new 3d printer, this one uses resin instead of filament. Much better detail.

![[Image: new-printer.jpg]](http://metalshop.nobucks.net/pix/new-printer.jpg)

I have it printing a case for a DMR hot spot (ham radio thing).

Also, recently picked up a new (to me) rotary table. It's too big for my little mill but I still have plans on getting a bigger one when the right deal comes along. This one came with a indexing plate, but unfortunately no crank. I was able to find something to use for the nozzle (for lack of a better term) so I'll be making a crank for it. No hurry tho, I still need to find a bigger mill!

![[Image: new-rot-table.jpg]](http://metalshop.nobucks.net/pix/new-rot-table.jpg)

I also bought the two parts to a press brake (finger and die) but it's only about 4" long and not worth taking a pic of ... yet. Typically I only need to bend something for a bracket - which is the reason I bought it. I needed to make a mount for my mobile antenna and 1/8" steel about 2" wide was a bit much to be doing in a vise with a hammer - the way I'd been making my brackets. After I make something that will hold onto them better in the press I'll take some pics.

That's about all for now. The rest of the stuff I've picked up are all radio related.

Edit: forgot the pic of the rotary table!

Posts: 4,460

Threads: 184

Joined: Feb 2012

Location: Missouri, USA

(08-07-2019, 06:58 PM)Vinny Wrote: Also, recently picked up a new (to me) rotary table.

Edit: forgot the pic of the rotary table!

8 inch, 10 inch ...?

Willie

Posts: 2,620

Threads: 100

Joined: Dec 2014

Location: Michigan

The following 1 user Likes Vinny's post:

Highpower (08-08-2019)

Posts: 535

Threads: 39

Joined: Jan 2013

Location: Kelowna, BC, Canada

The following 3 users Like Hawkeye's post:

EdK (08-08-2019), Highpower (08-08-2019), arvidj (08-09-2019)

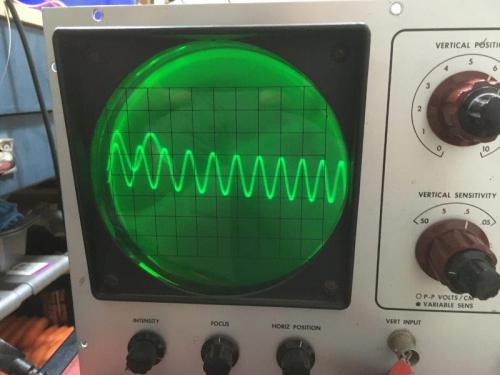

My latest 'delivery' was an old tube-driven oscilloscope that a friend gave me. It's a Bell & Howell Schools / De Vry model, made by Heath and assembled by a student. Still has the pencil notes (V1, V2, etc.) beside the tube sockets. I'm still waiting for one more tube to arrive. You'll note the fold-back on the left side of the trace.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

|

.

.![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)

and

and  I decided to go after the source of the problem. I invested in a combustion gas analyzer to check the furnace myself instead of paying the dimwits that installed it to come back out and check it. I found that the furnace was under fired and the stack temperature was too low, which explained the condensation buildup in the vent stack and causing it to rust out after two heating seasons. After clocking the gas meter and finding I was short on BTU's I ordered new gas nozzles one size up from the factory installed nozzles.

I decided to go after the source of the problem. I invested in a combustion gas analyzer to check the furnace myself instead of paying the dimwits that installed it to come back out and check it. I found that the furnace was under fired and the stack temperature was too low, which explained the condensation buildup in the vent stack and causing it to rust out after two heating seasons. After clocking the gas meter and finding I was short on BTU's I ordered new gas nozzles one size up from the factory installed nozzles.

![[Image: new-printer.jpg]](http://metalshop.nobucks.net/pix/new-printer.jpg)

![[Image: new-rot-table.jpg]](http://metalshop.nobucks.net/pix/new-rot-table.jpg)