Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

The following 3 users Like Pete O's post:

f350ca (09-29-2018), EdK (09-29-2018), Vinny (10-01-2018)

I've decided I need to improve my pattern-making setup, I don't do much woodwork at all but I'm going to need a couple of decent castings for the frankenmill project and a disc sander should be a useful tool. The frankenmill has spawned more spinoffs than Happy Days and this is the latest one.

I used the same pattern that I made for the potter's wheel head for my daughter, 12" diameter is smaller than I would have liked to make but I would have had to make a new pattern, bigger flasks etc so 12" it is. Another spinoff of this spinoff was a crucible lifting hoist and pouring trolley, my big steel crucible must weigh about 12kg empty and when I filled it up for the potter's wheel components it became clear I needed to make a crucible handling system for safety's sake. I haven't taken any photos of the hoist and trolley, take my word for it they are ugly as sin, made entirely from the scrap bin. Worked a treat though and I got the mould poured- then this happened about 5 seconds after I filled the mould:

So that's why you're supposed to put weights on top of the flask

Stuffed the flask and spalled the concrete

Pretty sure I'll be able to sand the two halves of the flask back to smooth surfaces without losing too much depth.

To my utter astonishment, the casting was still full when I broke it out.

Made that ugly casting round and flat, bored it to suit a spare motor from under the bench (actually the original motor from my lathe- 3hp 3ph motor- overkill for a 12" sander I'm sure) then I turned the end of an offcut of mild steel shaft to use as a balancing arbor. Used the balancing jig from the surface grinder, I had to remove a fair bit of aluminium from the heavy side to get it balanced.

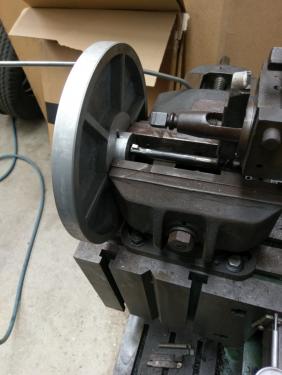

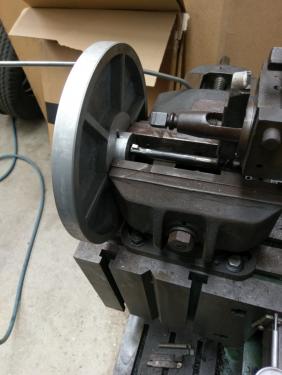

Off to the shaper to cut the keyway- a blind bore so a hole drilled at an angle to intersect the bottom of the bore gives the slotting tool somewhere to run out into.

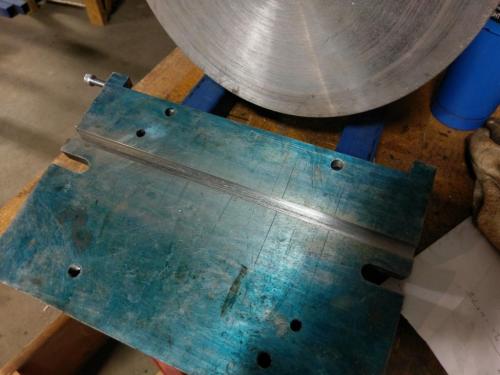

I cut the frame members from some RHS. A piece of machined .600 thick unknownium plate, that my shaper vice was bolted to when I bought it, will serve as the table for the disc sander. I mocked the parts up on the bench before heading in for dinner.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

The following 4 users Like Pete O's post:

f350ca (09-29-2018), JScott (09-29-2018), EdK (09-29-2018), Vinny (10-01-2018)

Today I welded the frame and bolted the motor down, then started some machining on the table. I'm going to borrow the mitre guide from my el-cheapo 300mm bandsaw, it's a piece of junk but it will do the job and will be easy to replace if it fails. It needs a 1/2" slot to slide in; I found a 1/2" x 5" side-and-face cutter amongst my collection, it looks like it is ready to be binned but it responded to a touch-up on the surface grinder with the sharpening jig I posted a while ago.

The slot was cut 1/4" deep, the sharpened cutter went through like butter. The photo is crap but the slot is good.

The table has to have a recess to fit around the disc, so that the pivot point for the table tilt can be as close as possible to the same plane as the front edge of the table. Cutting the recess was simple enough, but I scratched my head a bit over how to bevel the underside to 45 degrees. This is the setup I went with:

Nice to have enough room in the Z-axis to do this. I was also very thankful for the power feed on the knee; the bevel machining was all done in Z. It'll be a treat if I can ever get that J-head mounted on this machine so I can kick the stub-milling habit.

I got the machining on the table all finished before heading in for dinner tonight.

I'll be working on the table mounts next. I'd appreciate it if anyone who has a disc sander can tell me how much gap I should allow for the thickness of the sandpaper, I tried to buy a couple of sanding discs this morning but nowhere local has them.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Posts: 3,798

Threads: 184

Joined: Jun 2012

Location: Farmington Hills, Michigan

Looks like a fun project, Pete. You really lucked out with that leak in your flask.

I just went out and measured the gap on my Delta disk sander and it was about 3/32".

Tom

Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

Thanks Tom, I appreciate that. I'll most likely have the disc sander finished before I can get a sandpaper disc to put on it.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Posts: 482

Threads: 89

Joined: Oct 2012

Location: camillus (syracuse), ny

09-30-2018, 12:02 PM

(This post was last modified: 09-30-2018, 12:03 PM by the penguin.)

Pete,

The sander build is incredibly interesting, I’ve very impressed by the casting.

I’ve always been interested in other peoples techniques and equipment. I have a couple of questions.

Do you find a disc sander all that effective?? I have a 12” unit and hate it, unless I’m using the last 1-2” on the outside edge, I can remove metal faster with a file. Is it technique?? I worked for a number of years in a furniture factory (ran the maintenance dept), we had 3-4 units, that were never used.

I have a Jancy RadiusMaster 2” x 48” belt grinder, an Australian design and built, at one time marketed by Jancy (now Fien), that for me is a more viable tool. With the time and design work, you have involved in the project, you must believe they are a viable piece of equipment. Can you explain how you use it?? Maybe I’m missing something.

jack

Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

(09-30-2018, 12:02 PM)the penguin Wrote: Pete,

The sander build is incredibly interesting, I’ve very impressed by the casting.

I’ve always been interested in other peoples techniques and equipment. I have a couple of questions.

Do you find a disc sander all that effective?? I have a 12” unit and hate it, unless I’m using the last 1-2” on the outside edge, I can remove metal faster with a file. Is it technique?? I worked for a number of years in a furniture factory (ran the maintenance dept), we had 3-4 units, that were never used.

I have a Jancy RadiusMaster 2” x 48” belt grinder, an Australian design and built, at one time marketed by Jancy (now Fien), that for me is a more viable tool. With the time and design work, you have involved in the project, you must believe they are a viable piece of equipment. Can you explain how you use it?? Maybe I’m missing something.

Hi Jack-

I hope it'll be useful- I guess I'll be able to answer your questions better once I've got the thing finished! My plan is to use it for wood mostly, although I suspect it will see some metal also. I don't do a lot of woodwork but I'm finding with setting up a home foundry that my lack of woodworking gear is holding me back, as I need to be better set up to make patterns. A disc sander with a titling table seems to be an excellent way to shape pattern components and in particular to apply draft.

I have a 4" belt grinder that gets used all the time, however it only has one 4" contact wheel and is not variable speed. For ages I've had plans to build a 2x48 belt grinder with interchangeable platens, wheels etc- however large contact wheels suitable for knifemaking etc cost a bomb so I'll want to cast the wheels myself, which brings me back to pattern making.....what's a good tool for making an accurate 10" diameter wood disc with a 5 degree draft? I reckon a disc sander with a tilting table. I'll let you know how it goes!

I'm envious of your RadiusMaster, they are the Rolls Royce of belt grinders (I guess in the U.S. they are the Cadillac?), sadly priced way out of my reach. I've only seen one on the second-hand market once, I went and had a look at it and it was pretty beaten up, was missing some parts, had obviously been the workhorse grinder in the jobbing shop it was in. I put a bid on it and it went for about four times what I was willing to pay. It's easier for me to justify putting some time into something- especially using the machines I already have- than spending big money. So far the only money I've spent on this disc sander has been for the fasteners. I have some time on my hands at present and am catching up on some projects without having to justify my hours.

I have in mind to set this thing up on a portable base that will be directly inspired by the RadiusMaster videos I was drooling over a few years ago.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Posts: 2,328

Threads: 271

Joined: Jun 2014

Location: La Libertad, Philippines

09-30-2018, 08:36 PM

(This post was last modified: 09-30-2018, 08:40 PM by Dr Stan.)

Having taught foundry in higher education let me make a recommendation. Always use a 4X8 sheet of plywood or OSB on the floor where you will be pouring. Spills happen all too often and not only will you damage the concrete floor, but worse yet you can have small pieces of concrete flying through the air. The expansion of liquid H2O to steam is right around 1200 to 1 and concrete always retains water. Those small pieces of concrete will leave a mark at minimum. This is also the reason to pre-heat your scrap before introducing it to the melt. Just sit it next to the hole in the center of the furnace lid for 15 minutes and it will get plenty warm enough to drive out any trapped liquids. Excellent procedure to follow especially when using items such as transmission casings, small engine blocks, etc as a source of material. BTW, if you know of an engine rebuilder in your area pistons and connecting rods are some of the best sources of material you'll find. Very high quality aluminum. You don't even need to remove the rings or connecting rod pins. Just use a long hook to remove them from the melt prior to the pour.

One more thing, very good use of a grinder balancing rig to balance the disk.

Excellent looking disk sander. I'm sure you'll get plenty of good use from it working both wood & metal, or make two. One for wood & one for metal. Or two disks, one for wood & one for metal. Just drill & tap the center for a jack screw to make removal easier.

When I change out the sanding disks I use adhesive backed disks AND spray the disk with adhesive. Otherwise I usually have trouble getting them to adhere as well as I'd like.

Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

Thanks for that Stan, I know I shouldn't be pouring the mould on the concrete floor but...but...one more thing to do better next time. I'm sure I've got a big sheet of plywood somewhere that I can sacrifice to the cause. I was trying to avoid having to bump the crucible trolley up onto a lip but I guess a sheet of plywood shouldn't be too much of a challenge to roll it onto with 20" bicycle wheels.

I keep meaning to ask the engine guys for pistons. I've got a fair stock of aluminium on hand but it's in 'large format', i.e alloy wheels and transmission casings. I like the idea of pistons going straight into the pot without needing to be broken down. I've got six 16" mag wheels from an old Range Rover that are going to be a challenge to reduce to crucible size.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

The following 1 user Likes Pete O's post:

TomG (10-03-2018)

I put in a bit of time on the electrickery this afternoon, I put together a system to start the 3-phase motor on single phase power without running through my rotary converter. I want this thing to be portable enough to take it outside, or at least by the door, if I'm going to be making a lot of sawdust. The 3-horsepower motor is way over spec for a 12" sander so I can afford the power loss involved in a static converter. I used bits left over from my RPC build, although I had to fork out for the capacitors and the enclosure.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Posts: 2,620

Threads: 100

Joined: Dec 2014

Location: Michigan

I used static convertors on both my pedestal grinder and surface grinder. I didn't build 'em tho, only needed small ones so I bought them. The ones all the tool suppliers sell for $100+, the manufacturer sells the same one on ebay for $40. That's the route I took. Never had a problem with either grinder not having enough power.

|

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)