Posts: 4,463

Threads: 184

Joined: Feb 2012

Location: Missouri, USA

Used properly yes. But I can still bounce a part off a parallel with a dead blow hammer with too much force. That's what I normally use. It only takes a "thou" or two to end up with a sliding parallel. I find I'm much more careful with how hard I swing a small lead hammer vs. a plastic dead blow though. I guess subconsciously I feel like the plastic hammer is a "toy" and I have to swing it harder.

Willie

Posts: 432

Threads: 27

Joined: Feb 2016

Location: Woodstock:GA

(10-27-2017, 09:01 AM)awemawson Wrote: 'Dead blow' hammer stops the bounce back - (hollow hammer filled with lead shot)

Thank you, using a brass hammer, got a dead blow I can try...

(10-27-2017, 08:38 AM)Highpower Wrote: I run into that from time to time if I get in too much of a hurry and tamp down on the part a little too hard. It bounces back off of the parallel(s) just enough to let them slide under the part. Light taps work better for me. Possibly a difference in the materials between your blank and your 1-2-3 block causing a difference in rebound?

Did you deburr the edges of your blank after milling? I've been caught up by a sharp edge of a part hitting an inside corner of the vice in the past as well. Again my fault, for being in a hurry and deburring 11 edges of a block instead of all 12.

Thank you good points, regarding the bounce I do pound, will try backing off, yes deburr all 12 edges LMAO

Greg

Magazines have issues, everything else has problems

Posts: 2,328

Threads: 271

Joined: Jun 2014

Location: La Libertad, Philippines

The following 5 users Like Dr Stan's post:

f350ca (11-06-2017), JScott (11-07-2017), Vinny (11-07-2017), Mike E. (11-07-2017), EdK (11-07-2017)

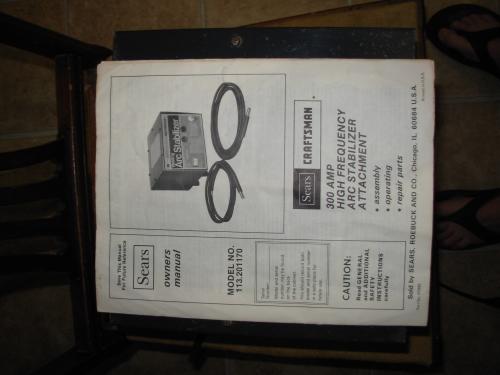

Sears Craftsman arc stabilizer. For converting an AC/DC welder into a TIG. Best I can determine is that it dates from 1984 and looks brand new!

Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

The following 3 users Like f350ca's post:

Pete O (12-04-2017), EdK (12-04-2017), Hopefuldave (08-18-2019)

Finally tracked down a shaper vice. 10 inch jaws, tips the scale at 110 pounds

![[Image: 2D_d4n7otHOCLQkiFcHUG1k7tfJ9rDQl91A4MKHm...37-h716-no]](https://lh3.googleusercontent.com/2D_d4n7otHOCLQkiFcHUG1k7tfJ9rDQl91A4MKHm-Q3hJeuELMYJj-6NW9nUwcS8wbjaX5wkJN1_VtNSZX6EmwG72rvOtYCHG0QgkQjvQhWTNlpNL1JpC0RuTD5YUyn7oMmXJcJ6h8hLwQZrWmjF7D6rUF4ZL9ZekfGzYoqnYspNdL7iS_w3FTvUdWRlThFrgXfd-dc2smKX0-ptcpEItUy9Hb9iQzqXn8E8OROEBKVRj3daFIXzeYxtmAosS1DpZEjYh6VOItV46wt7YMyzTSzBIEljv7qTJXs1fWaVZ2581EEaUQtdd2K_kXY_7pXKLlDkyLAqAVsA82CHo3M3K2iDluARZrTx1rCpNMPc7aZkVwrQ3f1hF69lf5ltspRMz48Ht5IH8sW1j3wXjU25eTSiFFHup1oz1zq9YrnRD4-FsafKQpjamarQJW3k0VlgWXwJ1ig105A0Ann7n5krWBwL7b-LDQuAXY3pCWJA6O2QGE6DGWWdVf98VseVHHy5idf-d0FXZZAA_IItkW7qkP_c3Zh1gKSq4YsdWXiofQdHGE-_Ix-KEYUbGggjNfYoeNJHD6lMFjvJx5pPouVo_zOcxQ_RB0_wjyqG3As9UA=w537-h716-no)

Free advice is worth exactly what you payed for it.

Greg

Posts: 130

Threads: 17

Joined: Dec 2016

Location: Melbourne, Australia

(12-03-2017, 09:55 PM)f350ca Wrote: Finally tracked down a shaper vice. 10 inch jaws, tips the scale at 110 pounds

<snip>

That's much nicer than this oldie I picked up last week. 150mm jaws and about 26kg.

Steve

Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

Good stuff Greg, at a glance that looks identical to the one I found, I remember now you asked me about the weight and I forgot to reply after weighing mine, 48kg / 105lb. Makes a big difference after trying to make do with a mill vice.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

I caught up with Steve G the other day- more on the reason for that in a couple of weeks- but he was extremely generous to me and donated the magnetic swarf tool that he posted about recently. Thanks Steve, my chip trays have never been cleaner and even the joints in my concrete floor are feeling the love!

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Posts: 130

Threads: 17

Joined: Dec 2016

Location: Melbourne, Australia

All good Pete - great to finally catch up and glad you found the swarf tool useful.

I've found mine really useful, and use it particularly to clean up around the lathe after every use. Even if I'm half way through a job and have to call curtains for the night I'll still give it a run around on the floor. Helps to keep peace in the house when neither myself or the dogs are dragging swarf in on our paws...

I'm hanging out for Christmas to see what Santa fronts up with ;)

Steve

Posts: 2,620

Threads: 100

Joined: Dec 2014

Location: Michigan

This showed up yesterday and I promptly put it together. It was a lot easier to put together than the 3D printer was, that's for sure. Only one acrylic piece to peel the paper off of. The nuts used for the frame didn't have very high quality control, a few of them had to visit the grinder so they'd fit - too fat! Must have something to do with the holidays!

![[Image: pcbmill.jpg]](http://metalshop.nobucks.net/pix/pcbmill.jpg)

So far I've only been able to move it around, in the process of installing LinuxCNC on the laptop to see what I can do with hit. I plan on using it for PCBs, but I'm sure it'll be used for other projects too.

Posts: 340

Threads: 24

Joined: Aug 2014

Location: Seattle, WA

Very cool, Vinnie!

Mike

SB 10K (1976) Rockwell vertical mill (1967) Rockwell 17" drill press (1946) Me (1949)

|

![[Image: pcbmill.jpg]](http://metalshop.nobucks.net/pix/pcbmill.jpg)