Posts: 4,463

Threads: 184

Joined: Feb 2012

Location: Missouri, USA

(09-25-2017, 09:18 PM)contraptioneer Wrote: I`m doing the inserts as I`m not confident of the ability of the aluminum to hold threading long term. I know there is better aluminum for the job but the 6061 is the most affordable for me. I`m retired and on a very fixed income. I Will take pics along the way.

Looking forward to seeing the pics Ron.

What will you be using to lay out the holes with? And what type of inserts will you be using? Helicoil, Time-Sert, other?

Willie

Posts: 3,798

Threads: 184

Joined: Jun 2012

Location: Farmington Hills, Michigan

The following 2 users Like TomG's post:

EdK (09-26-2017), DaveH (10-07-2017)

Mild steel is about the same cost as aluminum plate, but much stronger and more durable. That means it's not as apt to get beat up during use, and you won't have to put thread inserts in the holes, AND it's magnetic, so you can stick your magnetic base to it.

Just something to consider.

Tom

Posts: 30

Threads: 3

Joined: Sep 2017

Location: Michigan U.S.A.

The sub plate will be anchored to the mill table with 6 5/16-18 bolts and will in effect become the new milling table which I think will negate any change made by the milling process once it is bolted down. Once all the spot drilling, boring, tapping and cleanup is done and the new table is anchored I intend to surface with a fly cutter very lightly. My intention here is to end up with a tooling surface that is perpendicular to the spindle or as close as the fly cutter will allow.

I`m also using the spindle to gently scribe the 1 inch x 1 inch grid for boring and tapping. Thinking this should insure the table also being square in the X-Y travel.

I purchased the 6061 plate for $24.00 with free shipping and could not find any steel comparable to that price. The closest I found was more than $50.00 plus shipping.

As far as inserts I am making them out of 7/16-14 all thread bored and tapped 5/16-18 ID. Then just cut them to length on the band saw and cleanup the burrs. I will use red 272 loctite to keep the inserts in place. I have used the red before and it is some tough stuff requiring heat to do any disassembly.

.

Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

What your planning sounds very good, but you may find the plate is very handy for a lot of operations where it isn't fastened flat to the table. I made one out of a scrap of 1 + aluminium from an aircraft plant. Comes in handy for a lot of odd set ups.

![[Image: _t6JUTwPuXCP3TL-vrm2fzQ4PfnFt1sXnA6V6uDq...2-h1276-no]](https://lh3.googleusercontent.com/_t6JUTwPuXCP3TL-vrm2fzQ4PfnFt1sXnA6V6uDqjjSG-Gm10J75fL9ojvpXR3Ik873U6EbVrpAMZMuhKUUEiPpfLnbrC34BYxQBSYiPUQNCotk-tsXXL0kaydaJLF-9FkUY_KAKURu8Jee4OOm8dzdtvlrqONEJMKedln65rsoya3gWVqtqOvHJYsKYFYZXFPm1odeuK0pJWbnqMtbXSMsced73oKw8akAaJmCdzy8j69frkHnmJkZUGTy4FSVPV0UeD7Mj3sXHnTfq2vg-igWNVzHR-_r97AeM7Td5i7veCUwIkZQyEVe0j3eIDyuf67BL7OIs8W_5j8Vn0ThD4Wu5WJDTNK9HwCHnCOqjoED5lEybneaOHVwXe6PODWv88QB1Ot54tzfyNwm_gA8WlV4X8istTrz3XuucDcqA4juuUe7XwaHsc70LYCSxhoC_0LvAJfTOfxHDfXG_HQkWkUysfaaJ93FcfKxUbVuODtXl2neruGLoeWcik_KOo9AH7MF3WlV_-SIv-uX8dpUACtW-Bct-ZrO_t5iTlh7hz2GjxeeoALDdlLXG0RT757T4_V-CW58cIW1zpm-otTvwOlRVc3jVN-hfyqlxd4x5jQ=w1702-h1276-no)

Free advice is worth exactly what you payed for it.

Greg

Posts: 30

Threads: 3

Joined: Sep 2017

Location: Michigan U.S.A.

F350ca; I see in the pic in your post that your mill table has 3 T slots for fixturing where as my mill has but one, which is the main reason for the new tooling plate. The single T slot on mine is just way to limiting. I do like the idea of using the plate non anchored as well. With so little experience on the mill it is sometimes hard to know what might be useful in the future. At this point though I can see where there could be uses for several different tooling plates in different sizes and configurations. I have been a lurker here for a while and there is so much knowledge and experience here that I have seen and I`m sure I can benefit greatly by being here.

Posts: 30

Threads: 3

Joined: Sep 2017

Location: Michigan U.S.A.

The following 2 users Like contraptioneer's post:

EdK (09-28-2017), f350ca (09-29-2017)

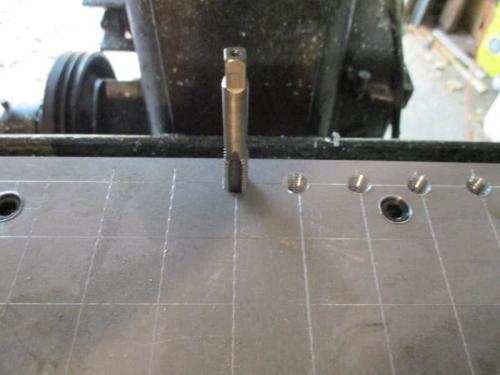

I finally got some pics taken.

This is the plate anchored to the milling table. Ready to layout the X and Y lines using the spindle to scribe the lines.

Lines marked out and 1st 2 holes drilled and tapped.

Slow but making progress.

Posts: 30

Threads: 3

Joined: Sep 2017

Location: Michigan U.S.A.

The following 1 user Likes contraptioneer's post:

EdK (09-28-2017)

Guess I should also say that I am starting my tap using the spindle for about 4 revs and finishing by hand so I can feel the stress on the tap.

Posts: 2,620

Threads: 100

Joined: Dec 2014

Location: Michigan

You need a tapping head and a spiral point tap!

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)