Posts: 691

Threads: 14

Joined: Feb 2015

Location: Oakland, California

@ Ed - get your mind out of the gutter, Lad! I know this is the internet, but not everything is pron here.

Actually, that gag comes from my teen years. I worked for $4/hr cash, with a bottle of Jack for holidays. The gig was repairing lawnmowers. George, the "owner" of the business was a true dropout from society, and literally, a skinny, dirty hippy, unreconstructed from back in the day.

Anyway, George was cobbling together a long ramp to roll mowers up onto the workbench, and I asked why, and he asked why I was asking. I reached down with one hand, lifted it by the pull-start housing and set it on the bench, effortlessly. George just said "Oh" and walked away.

Posts: 8,891

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

The following 1 user Likes EdK's post:

Mayhem (10-07-2016)

(10-06-2016, 05:54 PM)Roadracer_Al Wrote: I know this is the internet, but not everything is pron here.

I know everything is not pron but a lot of it is porn.

Ed

Posts: 536

Threads: 39

Joined: Jan 2013

Location: Kelowna, BC, Canada

The following 2 users Like Hawkeye's post:

f350ca (10-10-2016), DaveH (10-10-2016)

10-09-2016, 10:03 PM

(This post was last modified: 10-09-2016, 10:05 PM by Hawkeye.)

Like pretty much everyone who's ever had a round-column mill/drill, I got tired of getting my hand dirty on the leadscrew while locking or unlocking the Y-axis. When i started to plan it out, I realized it was a pretty quick project. I won't bore you with a step-by-step description.

Here's the finished product. I do have some 1" screw-on balls that I was planning to use on the end of the handle, but there isn't enough clearance against the base casting. I may put a slight bend in the handle to allow it, but it seems to work well as is.

Unlocked.

Locked.

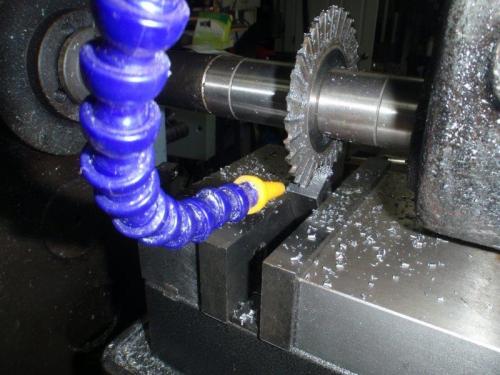

Okay. I'll give you one little detail. I cut the slots on the arms at 30 degrees to clear the link bar at both ends of travel. I clamped the bars at that angle and used one of my smallest slitting saws to make the cut.

I really like the way it works quick, clean and it really holds.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

Posts: 2,629

Threads: 101

Joined: Dec 2014

Location: Michigan

Besides doing moving, what makes it a lock? I don't see it doing anything.

Posts: 37

Threads: 3

Joined: May 2014

Location: australia

sorry vinny but i can see how it works , and in that pic it is in the lock possy if it was on my mill

johno

texx, proud to be a member of MetalworkingFun Forum since May 2014.

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

I'm guessing the set screw is ensuring that the bolt on the left is locking the gib. If so, is there any need for the pivot and link arm. Or is this preventing gravity unlocking it?

Hunting American dentists since 2015.

Posts: 124

Threads: 14

Joined: Jan 2016

Location: North Vancouver, Canada

Painted the Brideport today.

Turned out not too bad.

Posts: 124

Threads: 14

Joined: Jan 2016

Location: North Vancouver, Canada

The following 5 users Like Old Minger's post:

johnnyc14 (10-10-2016), f350ca (10-10-2016), EdK (10-10-2016), DaveH (10-10-2016), schor (10-26-2016)

Posts: 2,328

Threads: 271

Joined: Jun 2014

Location: La Libertad, Philippines

Posts: 124

Threads: 14

Joined: Jan 2016

Location: North Vancouver, Canada

Thanks. First time painting with a HVLP gun.

|