Posts: 240

Threads: 30

Joined: Mar 2014

Location: Planeta Rica, Colombia

The following 1 user Likes JScott's post:

EdK (04-10-2015)

I have been wanting a surface plate to add to the shop tooling and my wife found this Grizzly 12x18 on Amazon with free shipping (Prime). She ordered it Monday and it arrived yesterday. The plate itself is cheaper at Grizzly but the shipping is way more (saved $40).

http://www.amazon.com/Grizzly-G9652-12-I...face+plate

It looks pretty good and came packed fairly well in a light plywood box with two sturdy fiberglass straps. There is no damage to the edges or corners. As you can see in the picture it came with an inspection certificate showing the manufacturing date, etc. The ledges are 1.5"x1.5" and make it much easier to pick up this 73 lb plate. Plus they can be used for clamping. (By the way that is not my hand!)

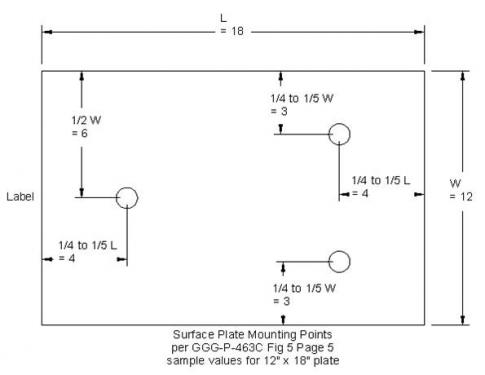

I have read up on supporting it correctly and found the usual info regarding mounting arrangements using the Airy points.

Then one of my next projects is buying a tool cart and building an internal "stand" out of angle iron to reinforce the top of the cart and provide a stout base for the support points . I can get this cart from Harbor Freight for $99.99 with a coupon. The surface plate will go in the top and my measuring tools, gages, blocks, etc. will go in the drawers. It should make a handy set up and keep the plate covered and protected.

JScott, proud to be a member of MetalworkingFun Forum since Mar 2014.

Posts: 691

Threads: 14

Joined: Feb 2015

Location: Oakland, California

Thats' a great idea, to use a rolling tool cart for the surface plate. And, you can keep tools in it.

Posts: 240

Threads: 30

Joined: Mar 2014

Location: Planeta Rica, Colombia

(04-10-2015, 11:05 AM)Roadracer_Al Wrote: Thats' a great idea, to use a rolling tool cart for the surface plate. And, you can keep tools in it.

The cart gets great reviews at HF and lots of folks talk about how sturdy it its. With a little upgrade to handle the concentrated weight of the plate I think it will do well.

And I promise to update with new pics when I get it all put together.

JScott, proud to be a member of MetalworkingFun Forum since Mar 2014.

Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

Congrats on the new surface plate! I use mine more than I ever thought I would.

Like you, I also found that info on the 3-point mounting recommendation and that's how mine is set up now. My dad had bought the 24x36x4 Grade A (and matching steel angle iron stand) from Enco and had it sitting on the four corners for the first few days. I corrected it and showed him the downloaded and printed info about "airy points."

Mine is on a solid mount, with four corner leveling screws. It's a "fixture" in the shop now, storing a lot of weighty items underneath. You'll have tools there too, but at least you'll be able to move it when it's in the way.

Posts: 4,460

Threads: 184

Joined: Feb 2012

Location: Missouri, USA

(04-10-2015, 11:27 AM)JScott Wrote: (04-10-2015, 11:05 AM)Roadracer_Al Wrote: Thats' a great idea, to use a rolling tool cart for the surface plate. And, you can keep tools in it.

The cart gets great reviews at HF and lots of folks talk about how sturdy it its. With a little upgrade to handle the concentrated weight of the plate I think it will do well.

And I promise to update with new pics when I get it all put together.

Sounds like a winning plan. Congratulations on the new addition.

Sadly I don't have room for a roll around, and I made my own stand. It sits stationary behind my mill and I made a lower shelf on it as well. My RFC is mounted on the shelf and keeps it off of the floor.

The problem with surface plates is that they are just like machines. Once you've had one for awhile, you start wishing you had a bigger one.

One of these days I'll get there.... maybe.

Willie

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

I'm just wondering if it is necessary to use the 'Airy Points' it's a smallish surface plate and quite thick and moving it about on a trolley.

I don't mean to be a 'party pooper' I'm just thinking to myself.

DaveH

Posts: 4,460

Threads: 184

Joined: Feb 2012

Location: Missouri, USA

Dave, I believe the reasoning is because that is how the plates are supported when they grind/lap them to their final finish. Best to keep everything same - same, just in case.

Mine is a smaller plate as well, and doesn't get moved around - but if the manufacturer says mount it on the three points, that's what I do.

No, it's not sitting on the angle iron, or touching the sides. It only serves as a 'fence'. There are two cross bars below that the plate actually sits on, on the airy points only.

![[Image: P2170001.jpg]](http://img.photobucket.com/albums/v82/Highpwr/Machining%20a%20receiver/P2170001.jpg)

Willie

Posts: 240

Threads: 30

Joined: Mar 2014

Location: Planeta Rica, Colombia

JScott, proud to be a member of MetalworkingFun Forum since Mar 2014.

Posts: 691

Threads: 14

Joined: Feb 2015

Location: Oakland, California

A few years ago, I saw on Craig's List a 120" x 56" surface plate -- yes, bigger than a mattress -- for just $500. I was trying to convince my bride that it would make an awesome dining room table, but she didn't take the bait. Smart woman I married. The rigging would have cost a fortune, and I doubt my dining room floor could take the weight.

Posts: 2,620

Threads: 100

Joined: Dec 2014

Location: Michigan

Yeah, that wouldn't even fit in the back of my truck.

|

![[Image: P2170001.jpg]](http://img.photobucket.com/albums/v82/Highpwr/Machining%20a%20receiver/P2170001.jpg)