Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

Tom spoke about helix angle in one of his videos Ed. I'd imagine it is in his tool bit grinding video but I could be wrong. I'd expect machenery's handbook to have the necessary data on cutting ACME threads.

Watching Ken make the elevation nut for my mill, I stressed to me that it is very easy to go from too tight to sloppy loose in one cut. So test often.

Hunting American dentists since 2015.

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

(02-20-2015, 06:45 PM)Mayhem Wrote: it is very easy to go from too tight to sloppy loose in one cut.

I'll support that!

Steve

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 8,860

Threads: 319

Joined: Feb 2012

Location: Arizona/Minnesota

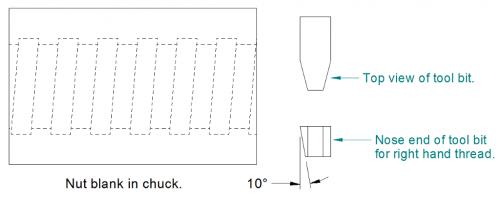

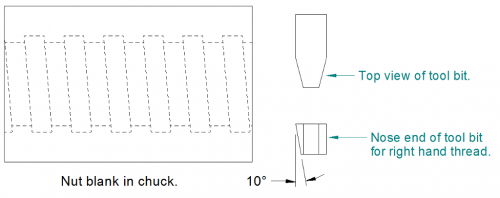

(02-20-2015, 06:27 PM)f350ca Wrote: I imagine the references are to grinding the tool to accommodate the helix angle.You need no or negative clearance angle on the right side of the cutter, the helix looks after that.

If we simplify the thread to straight lines a 1inch dia 10 tpi would be angled at 5.7 deg. So the left side needs probably a 10 deg clearance angle, and none on the right. Thats the sides with the tool facing the work ready to cut, opposite if your looking at the tool from the business end, or the other side of the lathe, if its not against a wall, then you'd need a mirror and Im not sure which side would be up then.

No idea how to get a sketch on here to give you a better idea Ed, draw up what you think I mean and I'll tell you if thats what I was thinking, if I can remember that far back.

Greg,

Is this what you're describing?

Ed

Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

Backwards Ed, need the clearance angle on the other side. Think of it going into the drawing of the thread you have.

WAIT Is this a left hand thread?

Free advice is worth exactly what you payed for it.

Greg

Posts: 8,860

Threads: 319

Joined: Feb 2012

Location: Arizona/Minnesota

(02-21-2015, 06:01 PM)f350ca Wrote: Backwards Ed, need the clearance angle on the other side. Think of it going into the drawing of the thread you have.

WAIT Is this a left hand thread?

Oops! Busted.

This is what I meant.

Ed

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

Wouldn't you need clearance on both sides when viewing it from the front?

Hunting American dentists since 2015.

Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

(02-21-2015, 08:17 PM)Mayhem Wrote: Wouldn't you need clearance on both sides when viewing it from the front?

No Darren, the clearance for the trailing edge of the tool is there by virtue of the helix angle.

That said, I always relieve both sides in case I have to make both a left hand and a right hand thread, and that foresight served me well recently.

Posts: 8,860

Threads: 319

Joined: Feb 2012

Location: Arizona/Minnesota

(02-21-2015, 08:26 PM)PixMan Wrote: ...

That said, I always relieve both sides in case I have to make both a left hand and a right hand thread, and that foresight served me well recently.

I was thinking of doing the same thing since I have to make both a right hand and a left hand nut.

Ed

Posts: 3,003

Threads: 51

Joined: Apr 2012

Location: Ontario

Thats it Ed. For an internal thread. My Oops, I was thinking external when I said clearance on left side. You can grind clearance for left and right but the tool will get pretty thin at the nose.

Free advice is worth exactly what you payed for it.

Greg

Posts: 691

Threads: 14

Joined: Feb 2015

Location: Oakland, California

The following 1 user Likes Roadracer_Al's post:

EdK (02-23-2015)

In another thread, I mentioned to Ed that I had given some consideration & research to backlash compensation on my RoC/POS mill-drill & mini-lathe. One design struck me as fairly easy to implement.

https://muc1.wordpress.com/anti-backlash-for-cnc/

My feeling is that if you're going to all the trouble, might as well add a feature that makes it a better machine.