Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Posts: 535

Threads: 39

Joined: Jan 2013

Location: Kelowna, BC, Canada

I have a 15:1 gearbox that I was thinking of using as the primary reduction for my vertical bandsaw. It runs fine on the belt drive countershaft, but we need to play, don't we? I just hope I get both of them back when I'm back in my house.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

I just found a three phase 1HP motor with a 7:1 reduction on it. I'm thinking of converting a wood cutting bandsaw that I have.

The fan cover is off, as I had to mark one of the blades to figure out the ratio. The will result in about 195 rpm, so I'll have to look at the pulley size on the bandsaw and work out what SFM I will end up with.

Hunting American dentists since 2015.

Posts: 175

Threads: 4

Joined: Sep 2012

Location: Dorset, UK

The following 1 user Likes Arbalest's post:

oldgoaly (06-19-2015)

I'd actually like to use my bandsaw for cutting both wood and metal. Can you get the speed range required by using a three phase motor and a VFD?

Arbalest, proud to be a member of MetalworkingFun since Sep 2012.

Posts: 2,344

Threads: 53

Joined: Feb 2012

Location: Spencer MA USA

(03-22-2015, 04:24 AM)Mayhem Wrote: I just found a three phase 1HP motor with a 7:1 reduction on it. I'm thinking of converting a wood cutting bandsaw that I have.

The fan cover is off, as I had to mark one of the blades to figure out the ratio. The will result in about 195 rpm, so I'll have to look at the pulley size on the bandsaw and work out what SFM I will end up with.

The nice thing about converting is it's usually mostly lathe work to make or modify pulleys and shafts. That's one machine you have which is operable.

Best of luck to you.

Nice work on your conversion, Shawn!

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

The following 1 user Likes Mayhem's post:

EdK (03-22-2015)

Smart arse

Hunting American dentists since 2015.

Posts: 190

Threads: 17

Joined: Aug 2014

Location: Ajax Ontario Canada

Nice conversion. I need to slow mine down too, but I will take the route of a dc motor which I picked up a while ago for $100.

Posts: 41

Threads: 1

Joined: Aug 2014

Location: Massachusetts

The following 1 user Likes Charles Spencer's post:

PixMan (06-19-2015)

06-18-2015, 10:16 PM

(This post was last modified: 06-18-2015, 10:20 PM by Charles Spencer.)

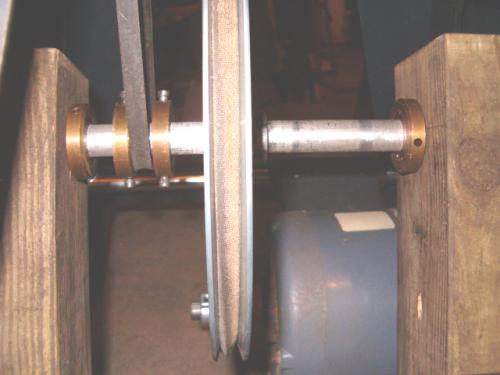

Well, I took a different and somewhat more comical approach with my Toolkraft (of Springfield, Massachusetts) 14" bandsaw. I used pulleys.

This what I posted somewhere at the time:

The saw in the first picture is a ToolKraft 14" Wood/Metal bandsaw. It was in good working order and clean when I bought it for $85.00. It doesn't look like it was ever used very much. It seems to be a copy more or less of the Delta Rockwell 28-200. Toolkraft was headquartered in Springfield and had a smaller plant in Enfield CT. It closed in 1984. This saw was made in Enfield.

I don't have a picture of the top pulley. Originally there was one belt that ran from the motor to the pulley running the wheels. That ran too fast to cut steel.

I added the large pulley and replaced the cone pulley on the motor with a 1 3/4" pulley, which was the smallest I could find. I created an Excel spreadsheet with the necessary formulas then ran it for different size pulleys. I got it down to 118 feet per minute.

I made an aluminum shaft from an old GP small pole. I mounted it through four brass bushings I had on hand. I made a support out of two pieces of 2"X4". About the largest wheel I could use was 10". To get the smallest diameter to drive the belt going to the saw I used the 3/4" shaft itself. The belt going to the saw runs between two additional bushings that each have two set screws...The 2"X4" supports are in turn supported by a cross piece I installed. I made it from a piece of iron bed frame. I have it attached to the saw frame with one bolt on each side. These are set up to provide tension adjustment to the second belt.

Charles

Charles Spencer, proud to be a member of MetalworkingFun Forum since Aug 2014.

![[Image: image.jpg]](http://s3.postimg.org/4gbtm83wz/image.jpg)

![[Image: image.jpg]](http://s3.postimg.org/hvyubocer/image.jpg)

![[Image: image.jpg]](http://s3.postimg.org/4gbtm83wz/image.jpg)

![[Image: image.jpg]](http://s3.postimg.org/hvyubocer/image.jpg)