Hi,

Seeing you guys are mucking around with the 45 mills I thought I would post this up as a mod to do.

Anybody with a HM52 mill or other Chinese mill will know doing interrupted cuts and general milling gives a clunking sound from the bad fitting splines between the female spline and the quill spline. The noise comes from steel against steel from them being such loose fit.

This mod fixes that by dampening the sound as the nylon pushed against the splines stopping them rattling back and forward.

I had some black nylon, Acetal or delrin (whatever you want to call it)left over from the 4wd lift kit I made and thought I could put it to use in the mill.

I first thought about using aluminum but decided not to because it would be to hard and just transmit the sound as well.

This is the unit removed from the mill after being pressed out. The taper part holds the pulley. I also removed the bearing to be able to grip it in the 4 jaw. While I was there I replaced the bearings.

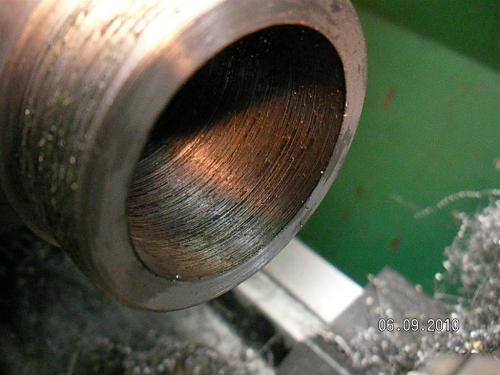

First up I bored out the top bearing/pulley unit as it was running out that much it would make the sleeve thin on one side.

Sorry this picture is out of sequence, but I forgot to take a picture, so I had to remove the nylon to take one after it was together.

Next I put the nylon in the lathe and machined it to be a press fit into the bore of the shaft. I left a collar on the top for no other reason than I thought I would. It doesn't show it in the pictures, but I also bored the nylon out to under size before parting it off. Nylon machines easy and comes off in ribbons which can get caught up if your not careful

The the hole lot back in the lathe to be bored to suit the quill spline. I just kept checking the fit after each cut until it was tight but could just be pushed in by hand with some force. Having it on the small (tight) size will be better than loose as it will wear in. The nylon will get a burr on the edge like in the picture, just use a sharp knife blade to cut it off.

After a year or 2 of use it has worked fine. some others have done it as well and have reported the same results I got.

Dave

Seeing you guys are mucking around with the 45 mills I thought I would post this up as a mod to do.

Anybody with a HM52 mill or other Chinese mill will know doing interrupted cuts and general milling gives a clunking sound from the bad fitting splines between the female spline and the quill spline. The noise comes from steel against steel from them being such loose fit.

This mod fixes that by dampening the sound as the nylon pushed against the splines stopping them rattling back and forward.

I had some black nylon, Acetal or delrin (whatever you want to call it)left over from the 4wd lift kit I made and thought I could put it to use in the mill.

I first thought about using aluminum but decided not to because it would be to hard and just transmit the sound as well.

This is the unit removed from the mill after being pressed out. The taper part holds the pulley. I also removed the bearing to be able to grip it in the 4 jaw. While I was there I replaced the bearings.

First up I bored out the top bearing/pulley unit as it was running out that much it would make the sleeve thin on one side.

Sorry this picture is out of sequence, but I forgot to take a picture, so I had to remove the nylon to take one after it was together.

Next I put the nylon in the lathe and machined it to be a press fit into the bore of the shaft. I left a collar on the top for no other reason than I thought I would. It doesn't show it in the pictures, but I also bored the nylon out to under size before parting it off. Nylon machines easy and comes off in ribbons which can get caught up if your not careful

The the hole lot back in the lathe to be bored to suit the quill spline. I just kept checking the fit after each cut until it was tight but could just be pushed in by hand with some force. Having it on the small (tight) size will be better than loose as it will wear in. The nylon will get a burr on the edge like in the picture, just use a sharp knife blade to cut it off.

After a year or 2 of use it has worked fine. some others have done it as well and have reported the same results I got.

Dave