08-02-2014, 10:13 PM

I picked up a set of 5C collets a while back, along with a spin indexer. and there have been a few times I've seen the advantage of having a fairly precise work-holding method for the lathe that allows the stock to extend into the spindle.

I got the chuck finished today, so it's time to post the build. I followed Pat Ioop's design, with a few small revisions.

The back plate started out as a broken lump of cast iron, just barely large enough for the required piece. The big bandsaw did a good job of trimming it to an octagonal shape.

A 10 1/2" four-jaw is just the ticket for roughing out a big piece of cast...

But, when it comes time to check the fit of the thread on the spindle, without removing it from the chuck, you have to wrestle the whole assembly around to screw it onto the spindle. Amazingly, even with the weight of the four-jaw hanging way out from the spindle, the register surface inside the chuck had a TIR of only around 4 thou.

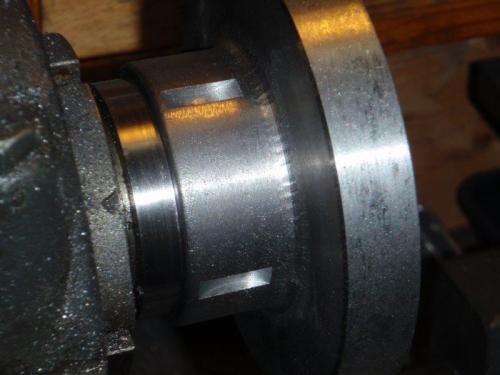

In order to make it easier to loosen the 5C chuck from the spindle, I cut four slots in the neck to allow use of a spanner.

Next, I needed a big chunk of steel to make the nose piece for the chuck. It takes along time to cut through a 7" x 4" cross section. The first cut gave me a 40 pound block.

By the time the block was reduced to a 5 1/8" octagon, 4" long, it was reduced to 25 pounds. The long rod in the tailstock is my wiggler - 10" of music wire with a collar clamped on to make a better place to reference the DTI.

The nose piece is roughed out to a bit larger than required and a 1" hole drilled through it.

The nose piece was turned around and indicated carefully to keep it concentric. Then the inside features were shaped out with a boring bar. Note the stylish spiral knurling on the outside of the piece... Oh, alright! it's chatter! Ya happy now? I found out I had issues with the spindle bearings.

I found out I had issues with the spindle bearings.

End of part 1.

I got the chuck finished today, so it's time to post the build. I followed Pat Ioop's design, with a few small revisions.

The back plate started out as a broken lump of cast iron, just barely large enough for the required piece. The big bandsaw did a good job of trimming it to an octagonal shape.

A 10 1/2" four-jaw is just the ticket for roughing out a big piece of cast...

But, when it comes time to check the fit of the thread on the spindle, without removing it from the chuck, you have to wrestle the whole assembly around to screw it onto the spindle. Amazingly, even with the weight of the four-jaw hanging way out from the spindle, the register surface inside the chuck had a TIR of only around 4 thou.

In order to make it easier to loosen the 5C chuck from the spindle, I cut four slots in the neck to allow use of a spanner.

Next, I needed a big chunk of steel to make the nose piece for the chuck. It takes along time to cut through a 7" x 4" cross section. The first cut gave me a 40 pound block.

By the time the block was reduced to a 5 1/8" octagon, 4" long, it was reduced to 25 pounds. The long rod in the tailstock is my wiggler - 10" of music wire with a collar clamped on to make a better place to reference the DTI.

The nose piece is roughed out to a bit larger than required and a 1" hole drilled through it.

The nose piece was turned around and indicated carefully to keep it concentric. Then the inside features were shaped out with a boring bar. Note the stylish spiral knurling on the outside of the piece... Oh, alright! it's chatter! Ya happy now?

I found out I had issues with the spindle bearings.

I found out I had issues with the spindle bearings.End of part 1.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

But then, every chuck needs to be coaxed into its optimum position. I loosened the bolts and gave it some careful taps. That brought it down to 0.0015-ish. I can probably tweak it a bit closer, if I take some time with it.

But then, every chuck needs to be coaxed into its optimum position. I loosened the bolts and gave it some careful taps. That brought it down to 0.0015-ish. I can probably tweak it a bit closer, if I take some time with it.

Mike

Mike