I have previously mounted iGaging DROs on two mills and a lathe, so it makes sense to have them on the Swedish lathe with the metric dials. While I have learned to think in terms of turning with a depth of cut of 1/2 a millimeter or 2 millimeters, I'm more comfortable thinking in thousandths of an inch.

I started with the tailstock DRO. There aren't any depth markings on the tailstock barrel. With a travel of over 5 1/2", I like to know how deep I'm drilling. All of the components are on the back side of the tailstock, including the display.

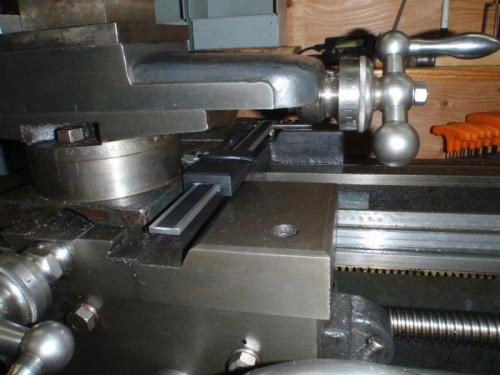

On to the crossfeed display. I kept the scale below the top of the carriage, so I don't lose any of the 11" turning diameter over the carriage. The reader stays under the compound, where it's out of the way.

The crossfeed features a full 10" of travel. Since the scale attachment is close to the carriage lock, I made up a new wrench by welding a crossbar to a deep socket. The 1/2" drive fits fairly well over the 12mm square lock.

Tomorrow, I should be able to get the bed DRO mounted.

I started with the tailstock DRO. There aren't any depth markings on the tailstock barrel. With a travel of over 5 1/2", I like to know how deep I'm drilling. All of the components are on the back side of the tailstock, including the display.

On to the crossfeed display. I kept the scale below the top of the carriage, so I don't lose any of the 11" turning diameter over the carriage. The reader stays under the compound, where it's out of the way.

The crossfeed features a full 10" of travel. Since the scale attachment is close to the carriage lock, I made up a new wrench by welding a crossbar to a deep socket. The 1/2" drive fits fairly well over the 12mm square lock.

Tomorrow, I should be able to get the bed DRO mounted.

Mike

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.

If you can't get one, make one.

Hawkeye, proud to be a member of MetalworkingFun Forum since Jan 2013.