Posts: 8,859

Threads: 319

Joined: Feb 2012

Location: Arizona/Minnesota

(11-27-2012, 08:05 PM)sasquatch Wrote: Not much exciting today, got the rest of the shaper parts buffed up, and got the shaper head repainted, now to get it all back together, and try it out.

Tommorrow is "Old Age Pension" day, so gotta head out to town to the bank, will let the new paint harden up for 24-36 hours or so.

We still don't believe you. No pictures, it didn't happen.

Ed

Posts: 1,827

Threads: 51

Joined: Apr 2012

Location: Oklahoma

11-28-2012, 06:10 PM

(This post was last modified: 11-28-2012, 06:11 PM by dallen.)

got in a fight with my chihuahua damn thing won I think. all over a biscuit. actually got hit by a 3 inch butt of a maple limb I cut off my neighbors tree

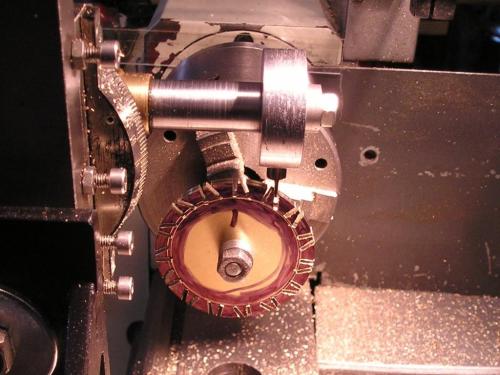

plus I worked on this part

dallen, proud to be a member of MetalworkingFun Forum since Apr 2012.

If life seems normal, your not going fast enough!

Posts: 3,798

Threads: 184

Joined: Jun 2012

Location: Farmington Hills, Michigan

Ouch! Better spend more time in the shop and less around trees.

Glad you came out only marginally scathed.

Tom

Posts: 825

Threads: 25

Joined: Jul 2012

Location: N. Bay Ontario

I had one or two of those over my 40 years cutting firewood, especially bad in deeper snow, can't really see them, cut off a sapling that is bent down by a dropped tree,, and---- WHAM!!!

(Sure smartens one up,, untill you forget again!!) Lol

sasquatch, proud to be a member of MetalworkingFun since Jul 2012.

Posts: 537

Threads: 15

Joined: Jun 2012

Location: Cambridge, England

(11-26-2012, 03:18 PM)stevec Wrote: Rick, thank you, I will try not to do that, I think maybe it's normal to just avoid situations that one is not prepared for. I hope I will not "turn off" in the future.

Steve

I'm sure I used to be uncomfortable around "disability" before I tried it out myself

but most folks are fine here in England, Back in my home town in Australia, folks were downright harsh, one old workmate actually said,

"If you're just going to roll around in that thing you should stay at home where people don't have to look at it" and followed up with "Don't you care how uncomfortable you make it for people that have to look at you".

Over here it's just that right now with the economy being what it is, an employer can get any quantity of fully able staff, I understand completely that if you're given a choice between a fully able worker and one that has any form of limitation you take the fully able guy, but what most Engineering employers don't seem to do is to look deeper into how much more I might be able to offer, but having said that I do actually have an interview lined up in the coming week, so fingers crossed

Best Regards

Rick

Whatever it is, do it today, Tomorrow may not be an option and regret outlasts fatigue.

Posts: 537

Threads: 15

Joined: Jun 2012

Location: Cambridge, England

(11-26-2012, 05:53 PM)doubleboost Wrote: The 1500 was a triumph engine

Not the best

Had a crank shaft like a bent coat hanger

John

Actually John, the BMC 1500 as fitted to the MGA was a completely different engine to the Triumph unit, Quite often the confusion is born out of the whole British leyland corporation debacle and the fact that Nissan bought the rights to the BMC 1500 engine for use in it's small commercial vans and pickups, but based it's very successful A series engine on the lighter Triumph engines, albeit in a very much better engineered outcome to that of the Triumph version. Nissan didn't change anything at all with the BMC engine, even continuing to use UNC and UNF threads, where pretty much all components were interchangeable but with the A series nothing was interchangeable with the Triumph.

The MGA was still a three bearing model that remained almost unchanged except for capacity up until the early MGBs, where it gained two extra main bearings and was still being produced in the eighties, while one might expect that the change from three to five main bearings was in order for the engine to be able to handle more power, when in fact many of the high end historic sports car racers look high and low for the three main bearing models as the lower frictional losses and crankshaft of adequate strength means that they actually produce more power with the same specification of pistons, cam and top end.

The change to bearing specification was made for two reasons one was that it had become deeply unfashionable for a producer to build three main bearing engines and there was a belief that as the engine was being used in heavier and heavier saloon cars as well as the sports cars low RPM lugging might cause increased fatigue issues with the three bearing crank, as it happens the change from a solid crank pulley to a rubberflex harmonic balancer was the step that finally saved the crankshafts from fatigue failure in the heavier saloons.

As you can all tell, I spent way too much of my youth inside historic racing car engines

Best Regards

Rick

Whatever it is, do it today, Tomorrow may not be an option and regret outlasts fatigue.

Posts: 8,859

Threads: 319

Joined: Feb 2012

Location: Arizona/Minnesota

(11-29-2012, 04:12 AM)Rickabilly Wrote: ... I do actually have an interview lined up in the coming week, so fingers crossed

Best Regards

Rick

Good luck with the interview Rick.

Ed

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

(11-29-2012, 06:39 AM)EdK Wrote: Good luck with the interview Rick.

Hunting American dentists since 2015.

Posts: 437

Threads: 24

Joined: Sep 2012

Location: Sicily

Hi all

made a start on the escapement for the new clock today.

I am limiting myself to using only the 7x12 with the parts that came in the box.--- A simple bench drill.---A dremmel type mini drill.-- and the normal hand tool found in a small shop.

All other tooling will be made .spending as little cash as possible.

The clock will use as little brass as possible to keep cost low.

This I hope will be the start of a plans book to enable those new the hobby to make something without spending lots of green crinkly stuff.

Brian

Posts: 1,827

Threads: 51

Joined: Apr 2012

Location: Oklahoma

dallen, proud to be a member of MetalworkingFun Forum since Apr 2012.

If life seems normal, your not going fast enough!

|

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)