Posts: 2,629

Threads: 101

Joined: Dec 2014

Location: Michigan

Got this one from Shars (aka discount_machine on ebay). Self lock cutoff tool, with inserts, holder and plastic case. A number of guys in the Logan group recommend this one.

![[Image: self-lock.jpg]](http://metalshop.nobucks.net/pix/self-lock.jpg)

Posts: 794

Threads: 52

Joined: Mar 2012

Location: Rochester, NY

Nice. I buy a lot of stuff from that guy.

Full of ideas, but slow to produce parts

Posts: 4,493

Threads: 187

Joined: Feb 2012

Location: Missouri, USA

I love that style of cut off blade especially for deep cuts. Sure beats the old style HSS blades (for most stuff).

Willie

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

I wish I had a lathe that could use a cutoff tool. Any kind would do. I've had no luck at all cutting off on the mini lathe.

Ed

Posts: 4,493

Threads: 187

Joined: Feb 2012

Location: Missouri, USA

(07-23-2023, 02:51 PM)EdK Wrote: I wish I had a lathe that could use a cutoff tool. Any kind would do. I've had no luck at all cutting off on the mini lathe.

Ed

This is all I've ever used on my mini. Just grind one out of a piece of HSS tool blank. But I have to grind and hone them until they are dead sharp for them to cut well. Experiment with the clearance angles too. But you can only go so deep with them before they start chattering depending on the length. Then it's time to finish up with the hack saw I'm afraid. Then again my mini still has the original 4 way tool post on it that you have to shim the tools to get them on center.

![[Image: Cut-Off__99518.1622831552.png?c=2&imbypa...mbypass=on]](https://cdn11.bigcommerce.com/s-4s9liwcv/images/stencil/original/products/373847/529005/Cut-Off__99518.1622831552.png?c=2&imbypass=on&imbypass=on)

Willie

Posts: 2,629

Threads: 101

Joined: Dec 2014

Location: Michigan

The following 1 user Likes Vinny's post:

Highpower (07-23-2023)

I put an AXA on my old mini. It held a parting tool quite well but you couldn't get too aggressive with it. Mounting the AXA meant removing the compound and replacing it with a T-Slot from the LMS micro mill. The T-Slot was too long so I had to cut some off, but the advantage to that was I could move the AXA around. I had more room for larger diameters and for threading I could move the tool to the back side and run in reverse.

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

(07-23-2023, 03:41 PM)Highpower Wrote: (07-23-2023, 02:51 PM)EdK Wrote: I wish I had a lathe that could use a cutoff tool. Any kind would do. I've had no luck at all cutting off on the mini lathe.

Ed

This is all I've ever used on my mini. Just grind one out of a piece of HSS tool blank. But I have to grind and hone them until they are dead sharp for them to cut well. Experiment with the clearance angles too. But you can only go so deep with them before they start chattering depending on the length. Then it's time to finish up with the hack saw I'm afraid. Then again my mini still has the original 4 way tool post on it that you have to shim the tools to get them on center.

![[Image: Cut-Off__99518.1622831552.png?c=2&imbypa...mbypass=on]](https://cdn11.bigcommerce.com/s-4s9liwcv/images/stencil/original/products/373847/529005/Cut-Off__99518.1622831552.png?c=2&imbypass=on&imbypass=on)

I've tried that one. No go. Maybe I need to check the angles on it. It came with a set of Accusize brand 5/16" HSS pre-ground lathe tool bits from Amazon.

Ed

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

(07-23-2023, 04:34 PM)Vinny Wrote: removing the compound and replacing it with a T-Slot from the LMS micro mill

I have that T-slot table. Just haven't gotten around to tackling it. The AC unit in my shop doesn't work well once it gets up into the 100s. It squeals like a banji. I think the heat distorts the housing and tweaks the motor bearings. It's a window unit. I can work in there in the morning briefly then need to exit to cool down. It's been in the 100 teens for the past few weeks.

Ed

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

The following 1 user Likes EdK's post:

Highpower (07-23-2023)

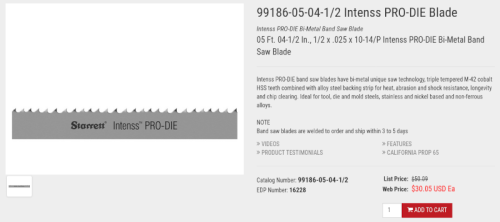

(07-22-2023, 10:49 PM)EdK Wrote: Ooooh, a Starrett box.

Ed

OK, nothing special in that box. Just a pricey band saw blade.

I've been working on my band saw for the past week trying to get it to cut straight. I tore it apart and replaced the blade guide bearings and the upper wheel bearings. Then did a complete alignment based on a gazillion YouTube videos I watched. I thought I had it nailed but cutting a piece of aluminum for a project proved nothing had changed. At that point I resorted to some beers to help me think. The only item I hadn't replaced or adjusted was the blade. I had looked at the existing blade and it looked fine. But I went ahead an bought a new one. This time I wanted a known good brand so I bought the Starrett blade. This morning I installed it and made sure everything was still in alignment and made a cut in a piece of 1/2 x 5/8 steel. It looked promising but it was really too small of a piece to judge the squareness of the cut so I cut a piece of 1 1/8" 41L40 rod for a project and it came out real straight. Need just a little more tweaking to get it perfectly straight though. But, it didn't cut all of the way through. It stopped just before it cut through. So that needs to be tweaked also. I can't believe how easily the Starrett blade cut through the 41L40 steel. It's a pricey blade but if it keeps performing like this it'll be my new band saw blade brand.

Ed

Posts: 4,493

Threads: 187

Joined: Feb 2012

Location: Missouri, USA

(07-23-2023, 05:59 PM)EdK Wrote: I've tried that one. No go. Maybe I need to check the angles on it. It came with a set of Accusize brand 5/16" HSS pre-ground lathe tool bits from Amazon.

Ed

Whenever I have trouble parting off it's usually because the front of the tool is rubbing the work somewhere below the cutting edge. I started marking the front of cutoff tools with a sharpie to see where it was rubbing and made changes as needed.

Willie

|

![[Image: self-lock.jpg]](http://metalshop.nobucks.net/pix/self-lock.jpg)

![[Image: self-lock.jpg]](http://metalshop.nobucks.net/pix/self-lock.jpg)

![[Image: Cut-Off__99518.1622831552.png?c=2&imbypa...mbypass=on]](https://cdn11.bigcommerce.com/s-4s9liwcv/images/stencil/original/products/373847/529005/Cut-Off__99518.1622831552.png?c=2&imbypass=on&imbypass=on)