03-27-2022, 04:38 PM

So far I'm somewhat disappointed with the PM mill.

One of the thrust bearings on the right side of the X lead screw is stuck on. I spent a good part of yesterday with emery cloth smoothing out the shaft.

It was galled rather badly. I got it so I can slip the other thrust washer on up to the stuck one without it binding. I'll have to deal with the stuck thrust washer before I begin assembly. May have to make a custom puller.

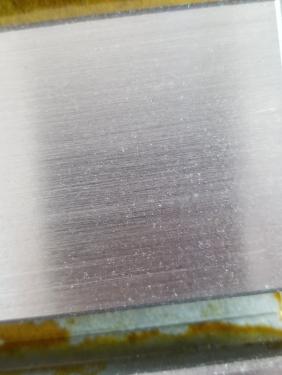

The surface finish on the table is a bit disappointing. It looks like someone did a hand job with a sanding block and some 220 grit sandpaper.

There are long gashes in the table dovetails. They aren't very deep so probably won't affect the operation of the mill but they still shouldn't be there.

The casting for the table didn't have enough meat to fully form the dovetail on both ends of one side.

There's a ding on the table surface that will need to be stoned out. Not a big deal but it shouldn't be there on a new mill.

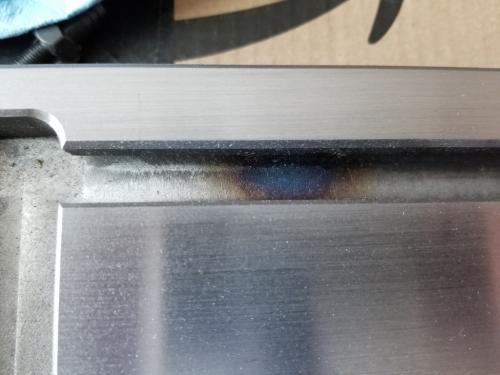

There's a burn mark on the table in one of the t-slots that goes all the way through and to the dovetail slide. Not sure how that could have happened but it shouldn't be there.

I think the table that was installed on this mill should have been rejected. Maybe it was and someone decided to use it anyway.

Had to split the base and the column to make them easier to handle. They will be coming into the house shortly then everything will be inside. Then reassembly can get started.

Ed

One of the thrust bearings on the right side of the X lead screw is stuck on. I spent a good part of yesterday with emery cloth smoothing out the shaft.

It was galled rather badly. I got it so I can slip the other thrust washer on up to the stuck one without it binding. I'll have to deal with the stuck thrust washer before I begin assembly. May have to make a custom puller.

The surface finish on the table is a bit disappointing. It looks like someone did a hand job with a sanding block and some 220 grit sandpaper.

There are long gashes in the table dovetails. They aren't very deep so probably won't affect the operation of the mill but they still shouldn't be there.

The casting for the table didn't have enough meat to fully form the dovetail on both ends of one side.

There's a ding on the table surface that will need to be stoned out. Not a big deal but it shouldn't be there on a new mill.

There's a burn mark on the table in one of the t-slots that goes all the way through and to the dovetail slide. Not sure how that could have happened but it shouldn't be there.

I think the table that was installed on this mill should have been rejected. Maybe it was and someone decided to use it anyway.

Had to split the base and the column to make them easier to handle. They will be coming into the house shortly then everything will be inside. Then reassembly can get started.

Ed