Posts: 4,460

Threads: 184

Joined: Feb 2012

Location: Missouri, USA

I found this on the web yesterday. I don't have space for a 3D printer but I am curious though. How does one print a block like this with a thin slot running through it?

I guess I'll have to see if I can something similar on the open market. I hate the little folded piece of sheet metal on my pocket rule that serves as a stop / pocket clip. Way too small of tabs that hold it onto the rule and it gets canted (out of square) if you slightly bump it.

Willie

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

The following 1 user Likes Mayhem's post:

Highpower (01-29-2022)

I'd print it on its back, so the slot runs from the bed of the printer through to the top. The screw hole is small enough that it will print the threads just fine with their axis running parallel to the bed.

Hunting American dentists since 2015.

Posts: 8,860

Threads: 319

Joined: Feb 2012

Location: Arizona/Minnesota

The following 1 user Likes EdK's post:

Highpower (01-30-2022)

(01-29-2022, 05:22 PM)Mayhem Wrote: The screw hole is small enough that it will print the threads just fine with their axis running parallel to the bed.

Or use a threaded insert.

Ed

Posts: 771

Threads: 48

Joined: Mar 2012

Location: Rochester, NY

For something like this, where you don't really need to torque it down, printed internal threads work great.

Full of ideas, but slow to produce parts

Posts: 4,460

Threads: 184

Joined: Feb 2012

Location: Missouri, USA

It really doesn't matter to me either way because I don't have a 3D printer anyway and will have to buy a clamp ready made.

I am tempted though to buy a set of the insert heating tips that Ed has. I've had of few of those inserts that had come out of plastic housings before and ended up having to try to glue them back in place. I'm wondering if it might be quicker/easier to just drill a new hole and melt in a new insert in some instances.

Willie

Posts: 8,860

Threads: 319

Joined: Feb 2012

Location: Arizona/Minnesota

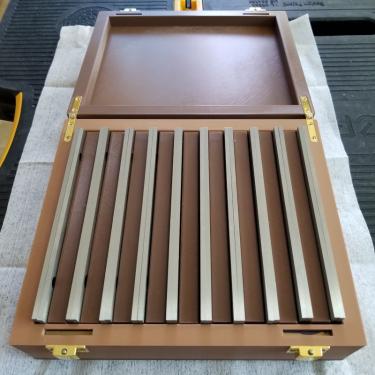

And yet another box. This time for my set of parallels. The box they came in wouldn't latch closed and it had a fake hinge that will fail soon because it's just a flap of plastic. This had happened to me before with this type of box.

The screws to attach the latches and hinges are 2-56 brass pan head screws. I had to turn down the head diameter and decrease the head height in order for them to fit the counterbores in the hardware.

Ed

Posts: 2,620

Threads: 100

Joined: Dec 2014

Location: Michigan

Till I took a closer look I thought it was a wooden box. Looks good!!