Posts: 2,629

Threads: 101

Joined: Dec 2014

Location: Michigan

A lot of folks were complaining where you measured it was .003-.004 off or out of round.

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

The following 3 users Like EdK's post:

Vinny (06-01-2021), Highpower (06-02-2021), f350ca (06-02-2021)

I measured the chuck register and there's about .0003" of TIR. I can live with that.

Ed

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

Printed a cover for the apron to prevent swarf from clogging up the gears. It's not perfect but it'll work for now.

Ed

Posts: 8,888

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

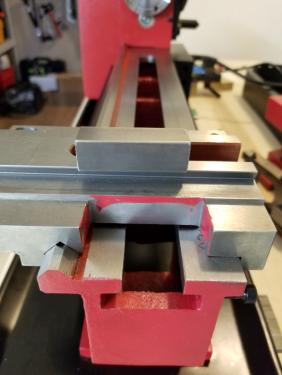

In preparation for installing a carriage lock I had to file the side of the saddle so I can bolt a piece of steel to it. My hand drilling skills don't exist so I'm going to wait to drill the mounting holes for when my drill press arrives next Tuesday.

Ed

Posts: 4,493

Threads: 187

Joined: Feb 2012

Location: Missouri, USA

The following 2 users Like Highpower's post:

EdK (06-05-2021), arvidj (06-05-2021)

(06-04-2021, 09:32 PM)EdK Wrote: ... My hand drilling skills don't exist ...

Ed

That is why I have a bunch of these now.

https://www.youtube.com/watch?v=gX7zVyN-pl4

Saved my bacon when I had to drill and tap the small holes in the cast iron base column of my mill to mount the limit switch rail for the power feed I put on the knee. The casting is not exactly flat nor round where I had to attach the brackets. Trying to hold a hand drill perfectly perpendicular in two different axis is not a gene that I possess. I can come close with one or the other but never both.

Where did you file on the side of your saddle? Everything looks factory ground.

Willie