01-23-2019, 10:40 PM

Because there were some oil leaks and a broken back gear bull gear tooth I decided to make it a project.

The disassembly of the Headstock and removal of the cone pulley with gear and spindle required a little ingenuity and adapted parts to accomplish. In addition the bearing races needed to be extracted by running a bead of weld with the MIG welder. Once cooled the races almost fell out.

The bull gear on the other hand was not so cooperative. As I only have LPG and Oxygen in the workshop reaching the required heat for the 1" x 5" dia. bull gear and melting point for the purpose bought 2.4mm Silicon Bronze brazing rods took about 2 hours on day with about 40deg temperatures in the workshop.

All up it took less than one week to finish and cost a little over one hundred dollars for parts. Here are a few pictures to give an idea of the procedure.

Head stock showing broken tooth

Head stock reassembled

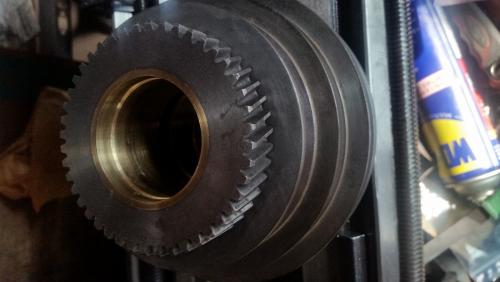

bronze bushed cone pulley and gear

front of Head stock with new race pressed fitted

Head stock back bearing race

silicone brazed bull gear

Bull gear tooth/teeth hand filed used needle files see finished gear below

pressing new bearing onto chilled spindle

repaired bull gear on right

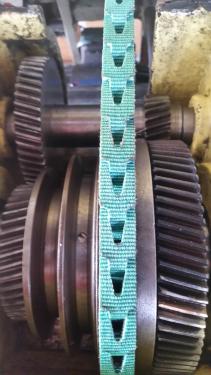

Head stock and back gear layout

VFD controls for Lathe

tramming the Head stock with the ways

tail stock alignment with head stock and ways

Many lathes have detachable Headstocks usually with three cap head bolts for tramming the head stock to the ways.

perhaps the foregoing may assist someone somewhere sometime.

John aka castellated nut

The disassembly of the Headstock and removal of the cone pulley with gear and spindle required a little ingenuity and adapted parts to accomplish. In addition the bearing races needed to be extracted by running a bead of weld with the MIG welder. Once cooled the races almost fell out.

The bull gear on the other hand was not so cooperative. As I only have LPG and Oxygen in the workshop reaching the required heat for the 1" x 5" dia. bull gear and melting point for the purpose bought 2.4mm Silicon Bronze brazing rods took about 2 hours on day with about 40deg temperatures in the workshop.

All up it took less than one week to finish and cost a little over one hundred dollars for parts. Here are a few pictures to give an idea of the procedure.

Head stock showing broken tooth

Head stock reassembled

bronze bushed cone pulley and gear

front of Head stock with new race pressed fitted

Head stock back bearing race

silicone brazed bull gear

Bull gear tooth/teeth hand filed used needle files see finished gear below

pressing new bearing onto chilled spindle

repaired bull gear on right

Head stock and back gear layout

VFD controls for Lathe

tramming the Head stock with the ways

tail stock alignment with head stock and ways

Many lathes have detachable Headstocks usually with three cap head bolts for tramming the head stock to the ways.

perhaps the foregoing may assist someone somewhere sometime.

John aka castellated nut

![[Image: TomsTechLogo-Profile.png]](http://tomstechniques.com/wp-content/uploads/2013/11/TomsTechLogo-Profile.png)