Posts: 2,629

Threads: 101

Joined: Dec 2014

Location: Michigan

Now THAT is a good idea. Wish I had speakers on this computer.

Posts: 8,890

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

Yea, I'm considering making one for my grinder and the flip side would be my combination wire wheel and deburring wheel.

Ed

Posts: 258

Threads: 30

Joined: May 2015

Location: NJ

Grrrrrr

Never mind guess I didnt explain wut im doing either that or didnt pots pics ;;;;lol;;;;;;..im brainstorming to accommodate a bunch of equi. in one area . The KEY is have it all functional accessible

.lt , keeps getting better . almost dialed in . stay tuned .ohh .i did get side tracked with checking runnout on the mill and making tool holders wrack , organizing

.

Yea thanks for ideas lota help u guys I know ya dont know whats in my pea brain see comments below and please dont take wrong way Im Joking

Keep in mind I already have gargle layed out

been thinkin bout this for months now .The lathe, mill tooling shelves and the most important fridge takes up ¾ of the one wall.

The Lathe will be placed in FRONT of the tooling shelves than I have about 6 feet of space for everything I spoke of . Never mind putting a moveable cut off saw that rolls out the door in front of this tier bench I am brainstorming .

Personal comments below and better pic of shop layout

Vinny Wrote:

Kenny. are you just putting everything against walls? Depending on the size of your garage you may be able to put things more centered there. If you need power, power it from above

Hey my coisin Vinny are you here to amuse me? I already have gargle layed out

see above and below for better picture of what I am describing . Btw with this layout and the bike removed I still have an open area of about 8 x8 up 10 -12 (with table saw and island benches pushed forward for any assembly big projects. Ohh no worries I did not hafta down size frige as of yet .If I do get a set of touches and need another BIG vice than im gona hafta build another bench with mini frige below it so weher still good right

Ed wrote :

Here's another idea Kenny.

And some links to various designs of flip-top stands.

Yea I saw some cool stuff not long ago with benches that had flip shelves that swung under bench for bench machines. kool looking great idea . but not practical for myself. I already have built a l shape double work bench with draws cabinets and hardware storage.

So like I was saying Already have a double assembly bench piggy backed to table saw (its also an optional bench when saw not in use) this island is off of L work bench mid way in Garage perfect as it can be moved changed rather easily . The one side of garage wall has 2 full roller cabinets and a drill press and ENCLOSED cabinets that extend all the way big door s . My Scooter (Motorcycle) is on that side and its area is totally sacred from any thing moving falling flame overspray chips and the like . I can roll lit outside if need be when doing something that may come close. Other than that it stays right were she sits .Ok gota get something goin off to 3 stops .One is gona to get some ¾ or ½ black pipe some U bolts clamps ect,,,,

at least get something to lay out with the 2 options I have already come up with WIP

Posts: 41

Threads: 1

Joined: Aug 2014

Location: Massachusetts

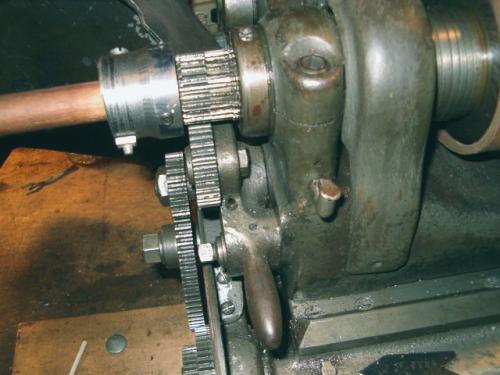

I did this a couple of days ago - a hand crank for my South Bend lathe. The handle is an old vise handle, the shaft is a birch dowel so as not to damage the inside of the spindle, and I made the collar. I made it so I could use threading dies on the lathe.

Charles

Charles Spencer, proud to be a member of MetalworkingFun Forum since Aug 2014.

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

(06-14-2015, 08:04 AM)PixMan Wrote: Creative way to do it!

Just be careful of the soft end. If's is a true (half-hard) brass it could chip and throw chunks at you rather than deform as some bronzes might.

Thanks Ken - judging by the dents on the end, I'm guessing that this will deform, rather than chip. The wall isn't that thick. If it does chip, it shouldn't be a problem as I will have my safety glasses on.

It is funny - I keep a set of glasses next to the bench grinder, so that I never give in to the temptation of just doing a quick job without them. I can't remember the last time I picked them up and used them, as I always seem to have a pair on my head since I got the lathe.

I had though of turning up a ring that would be an interference fit over the brass fitting. I was going to leave about 6mm (~1/4") sitting above the top, so that the lead protruded above the brass, after the ring was removed. However, I don't think I will need it. Besides - a few uses will tell me if the brass chips and if it does then I will go with the ring.

As I said - fishing stuff out of the junk box (inventory)

Hunting American dentists since 2015.

Posts: 968

Threads: 67

Joined: Apr 2015

Location: Australia

Managed to steal a couple of hours today and made a start on my rotary phase converter.

The 7.5hp motor I bought on the weekend had a big cast impeller of some strange sort on the output shaft

Fortunately whoever made this thing foresaw the need for it to come off one day, there are a couple of M12 threaded puller holes in the casting

Turns out a 42mm shaft has a lot of holding power, my oxy set is just about out of gas so I didn't want to blow it all away warming this thing up, used the small propane torch to warm up around the bore (this thing is one big heat sink, didn't want to warm up in a hurry) anyway after nearly busting both my puller and my pooper valve, the thing eventually moved

Got back to the jobs I was supposed to be doing for the rest of the afternoon, then stole a bit more time to make a stand for the phase converter. The motor will stand vertically in this frame, with the flange bolted down to the lower cross members. The cabinet with the electrickery will sit on top. Have to make some screw feet for it yet and some threaded bushes, the bushes will be welded to the lower cross members to accept the flange bolts. Nearly 6 meters (20 feet) of 40x40x2mm RHS in this thing.

The 240 to 415v transformer and all the capacitors etc should be here by the time we get back from our outback trip in a couple of weeks. Unfortunately it will be time for me to go back to work then too, don't know how I find the time to have a full-time job.

Lathe (n); a machine tool used in the production of milling machine components.

Milling Machine (n); a machine tool used in the production of lathe components.

Posts: 214

Threads: 19

Joined: Oct 2014

Location: SOUTH AFRICA,KZN,DURBAN

(06-13-2015, 03:36 PM)Kennyv Wrote: Ok starting to learn a few names .. and put a few faces together . Hey Ed nice Job on those compressor wheels . Mike nice Job on the auto Draw bar . I saw u last night On U-tube .Yure famous now bro... Stayed up till 2:30am and watched allot of tool changer Auto drawbar stuff Mods ..

Kenny

What's Mike's U Tube channel known as, same as he calls himself here ???

Would like to watch him in action as well

Let me know please

TIA

aRM

Posts: 8,890

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

(06-16-2015, 01:18 PM)aRM Wrote: ...

What's Mike's U Tube channel known as, same as he calls himself here ???

Would like to watch him in action as well

Let me know please

TIA

aRM

Here you go.

https://www.youtube.com/channel/UC6CvyvC...k3w/videos

Ed

Posts: 190

Threads: 17

Joined: Aug 2014

Location: Ajax Ontario Canada

The following 1 user Likes schor's post:

Mayhem (06-17-2015)

(06-16-2015, 05:20 PM)EdK Wrote: (06-16-2015, 01:18 PM)aRM Wrote: ...

What's Mike's U Tube channel known as, same as he calls himself here ???

Would like to watch him in action as well

Let me know please

TIA

aRM

Here you go.

https://www.youtube.com/channel/UC6CvyvC...k3w/videos

Ed

I didn't know Mike had a channel. I just subscribed (Steve S on youtube).

Maybe we need a sticky list of members that have youtube channels.

Posts: 1,827

Threads: 51

Joined: Apr 2012

Location: Oklahoma

The following 3 users Like dallen's post:

PixMan (06-19-2015), EdK (06-19-2015), f350ca (06-19-2015)

it was yesterday, and I pretty much finished up this little rifle I been working on.

dallen, proud to be a member of MetalworkingFun Forum since Apr 2012.

If life seems normal, your not going fast enough!

|