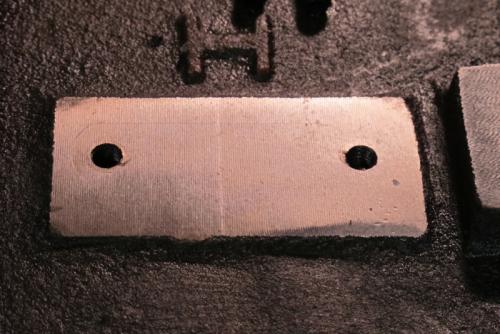

Since the mill power feed is on hold until a bigger lathe dog arrives, I decided to try to find out why my mill table has so much slop in it. I took the table off to look at my nut. Couldn't see much with all of the grease and oil on it so I removed it from the saddle and cleaned it up the best I could with denatured alcohol. The threads are worn so bad they look like pointed threads instead of acme or trapezoid threads. No wonder there's so much slop in the lead screw. The good thing is that the surface where the nut mounts on the saddle is a ground surface, unlike the raw cast iron surface that was on my lathe cross slide. I doubt replacement parts are available since the mill is 6 years old but I'll contact Enco and see what they say. Otherwise I might try Grizzly and see if they have something that might work. I haven't even tackled the cross feed which should be in worse shape since it seems to have the most slop in it.

The lead screw measures about .941" according to my micrometer. It's 10TPI and the closest acme thread to those specs would be a 15/16 x 10 TPI. That's a rare bird. The closest metric lead screw would be a 24M x 2.54, another rare bird.

Bummer, time to start searching for parts.

Ed

The lead screw measures about .941" according to my micrometer. It's 10TPI and the closest acme thread to those specs would be a 15/16 x 10 TPI. That's a rare bird. The closest metric lead screw would be a 24M x 2.54, another rare bird.

Bummer, time to start searching for parts.

Ed

![[Image: 625-10Acme.jpg]](http://img.photobucket.com/albums/v82/Highpwr/Shop%20Projects/625-10Acme.jpg)