04-18-2014, 02:33 PM

I discovered some time ago that my cross slide has way too much movement in it. I wondered why I could never seem to turn to a correct dimension consistently. It really reared its ugly head after I installed the DRO. It has about 15-20 thousands of movement. I tried the usual like tightening up the gib but that didn't do anything but make it hard to turn the cross slide dial. I played with the set screw on the cross slide nut to tighten up the play but that didn't help much either and it caused the cross slide to bind at some points on the lead screw. So I disassembled the cross slide and took some pictures in hopes of getting some tips on what I can do to decrease the amount of movement in the cross slide.

Some observations.

One thing for sure is I need to mill the underside of the cross slide where the nut sits to make a flat surface for it to sit on. Then I need to mill the nut surfaces flat so it will sit on that newly milled flat surface on the cross slide. I'll likely need to shim the nut to line it up with the lead screw. I think I need to take a very small amount off the diameter of the bushing so it can swivel enough to line up the nut with the lead screw.

I'm open to all hints and suggestions on how to fix this problem.

Ed

Some observations.

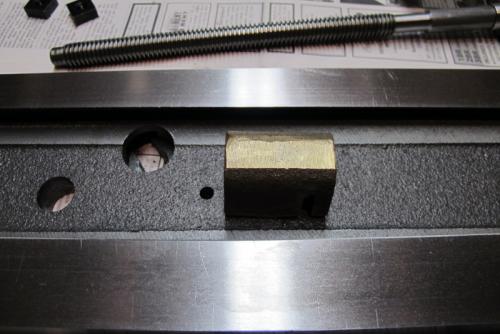

- The nut looks like it was made on a Monday using a grinder and a coarse file.

- The surface where the nut mounts on the underside of the cross slide is a raw cast iron surface.

- The bushing with the slot in it that the nut is supposed to sit in is a press fit and can't be easily swiveled to line up the nut with the lead screw.

One thing for sure is I need to mill the underside of the cross slide where the nut sits to make a flat surface for it to sit on. Then I need to mill the nut surfaces flat so it will sit on that newly milled flat surface on the cross slide. I'll likely need to shim the nut to line it up with the lead screw. I think I need to take a very small amount off the diameter of the bushing so it can swivel enough to line up the nut with the lead screw.

I'm open to all hints and suggestions on how to fix this problem.

Ed

try Country of Origin

try Country of Origin