Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

(02-02-2013, 01:09 PM)DaveH Wrote: Andy,

The register is more important than the threads, the important place to measure (with your gauge) is the inside of the taper.

Fix it to your lathe turn the spindle by hand and mark on the out side of the taper the point of maximum needle swing.

Take the ER chuck off the spindle and then screw it back on and measure it again - see if it coincides with the first mark.

If it does then the register is fine but the taper isn't coaxial to the cl [just for Mayhem] of the spindle.

A good place to start.

DaveH

DaveH, if by register you are refering to the face of the spindle shoulder I admit that it looks fine but without register to the unthreaded part of the lathe spindle (between the end of the threads and the shoulder of the spindle) the device will not run concentrically. Especially in light of the sloppy female thread of the piece of crap.

SteveC

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 68

Threads: 6

Joined: Apr 2012

Location: Hertfordshire, England

(02-02-2013, 01:57 PM)stevec Wrote: DaveH, if by register you are refering to the face of the spindle shoulder I admit that it looks fine but without register to the unthreaded part of the lathe spindle (between the end of the threads and the shoulder of the spindle) the device will not run concentrically. Especially in light of the sloppy female thread of the piece of crap.

SteveC

How can i check the internal size of the threads? A simple vernier good enough? If so, then i can check this

I dont have any internal micrometer though

Andy

b4dyc, proud to be a member of MetalworkingFun Forum since Apr 2012. Oh yeah

Posts: 2,685

Threads: 29

Joined: Feb 2012

Location: Nova Scotia, Canada

You can check it by comparing the way the collet adapter and your chuck screw on. Does your chuck wallow arround on the spindle right up to the shoulder? I think not in light of the fine concentricity you have with the chuck.

Busy Bee 12-36 lathe, Busy Bee Mill drill, Busy Bee 4x6 bandsaw, Homemade 9x17 bandsaw, Ad infinitum.

Posts: 8,892

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

(02-02-2013, 01:57 PM)stevec Wrote: DaveH, if by register you are referring to the face of the spindle shoulder I admit that it looks fine but without register to the unthreaded part of the lathe spindle (between the end of the threads and the shoulder of the spindle) the device will not run concentrically. Especially in light of the sloppy female thread of the piece of crap.

SteveC

Yup, as Steve said, the adapter needs not only an end registering surface but also an ID registering surface in order to be able to run concentrically.

Ed

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

(02-02-2013, 02:42 PM)EdK Wrote: Yup, as Steve said, the adapter needs not only an end registering surface but also an ID registering surface in order to be able to run concentrically.

Ed

That's correct, so the threads sloppy or not don't have a bearing on the ER's concentricity.

Andy - is it a home made item or bought, if it is bought it may well be too hard to turn, and it may need to be ground. You still need to check if it is registering correctly.

Where you had your gauge in the video (on the taper) is fine.

DaveH

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Just to confuse everyone - there can only really be one register.

DaveH

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Andy,

Looking at the video again ............. does it have a register? It is hard to see conclusively from the video.

DaveH

Posts: 8,892

Threads: 320

Joined: Feb 2012

Location: Arizona/Minnesota

(02-02-2013, 04:42 PM)DaveH Wrote: ... there can only really be one register.

DaveH

Good point Dave.

Ed

Posts: 4,495

Threads: 187

Joined: Feb 2012

Location: Missouri, USA

(02-02-2013, 04:39 PM)DaveH Wrote: That's correct, so the threads sloppy or not don't have a bearing on the ER's concentricity.

Dave, I've been down this road with my carbide grinder trying to get the wheels to run concentric. If the threads in the adapter aren't square to the center line of the lathe spindle when the adapter is tightened down, they can pull the adapter out of alignment. Especially if they are sloppy and have a reduced amount of engagement. You can have more compressive force on one side of the thread than the other, which results in the same pressure difference on the face of the register. Any excess space between the register and the adapter will allow it to move off center.

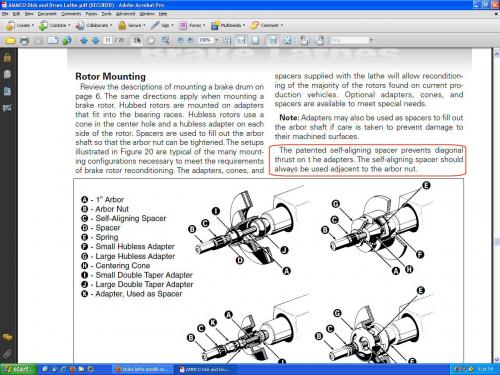

Brake drum/rotor lathes use a set of self centering washers behind the spindle nut to compensate for this.

Tightening the original sloppy spindle nuts on my grinder caused the wheel hubs to cock sideways by a couple of thousandths. A new set of tighter fitting nuts allowed the hubs to seat squarely on the grinder shaft and eliminate the excess run-out I was getting.

Just my

Willie

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Willie,

I agree with what you are saying, which is why Andy needs to check that his ER adapter is registering correctly and consistently.

Also we need to know where it is registering, or what it is using as a register.

DaveH

|