Posts: 157

Threads: 18

Joined: Apr 2012

Location: Damascus, Or

(11-14-2012, 08:06 AM)Highpower Wrote: They must like you Dan.

I bought a D1-4 backing plate from them that arrived with the cam pins missing from the box. They refused to just ship me the missing pins, and said I had to ship the thing back to them - but they would not ship the replacement to me until AFTER they received the returned plate.

Glad to hear they are taking care of you though.

I made a similar mistake in the early days after getting my mill. Fortunately I was using a ratchet wrench on the drawbar so no damage was done. The ratchet just spins when driven in the wrong direction. (Or unscrews the drawbar in reverse...) Cheap insurance.

They charged my card and shipped the next day. The card will be refunded when the old mill gets shipped back. They are paying for all of the shipping, I just have to transport the new and old from my work to home and back as I am reusing the shipping crate and we have a loading dock at work. I am hoping it shows up this Friday so I can get the old one shipped back early next week.

Dan

Collecting tools for 30 years.

Posts: 825

Threads: 25

Joined: Jul 2012

Location: N. Bay Ontario

Excellent service,, and really the way it should be,--- follow up on customers problems. look after them, and your business will thrive.

Nice to read this great service in this day of "Who Cares!"

sasquatch, proud to be a member of MetalworkingFun since Jul 2012.

Posts: 157

Threads: 18

Joined: Apr 2012

Location: Damascus, Or

Well, today was a little hectic. The new mill arrived at my workplace in the morning and I hauled it back to the shop and with help from my boss we unloaded the mill and placed it on the stand. The old mill is now attached to the shipping pallet and ready to ship back to Enco. This is important because I had to use my credit card to get the replacement mill shipped out so getting the old mill back is a big deal financially. So far the guys at Enco have been great to work with. Once the old mill is on the truck I can breath a sigh of relief. I will post some pics tomorrow of the replacement mill. Still alot of work to get back to square one but I am feeling lucky that it is going to work out ok.

Dan

Collecting tools for 30 years.

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

You are one lucky.....

I'm so tempted to try this with Kondia but given they stopped making manual mills 15 years ago I don't like my chances!

I for one am looking forward to see the pics and any planned mods (well intentional ones) that you will make to the new mill.

Hunting American dentists since 2015.

Posts: 157

Threads: 18

Joined: Apr 2012

Location: Damascus, Or

Well, finely an update. I didn't get any pictures of the un-boxing as we went at it fast and furious. The first business was cleaning the shipping grease off of all of the bare surfaces. At first glance the new mill looked exactly like the old one but there are some subtle differences. The color blue is a lighter shade and not done as well. More overspray and dings and chips. The metal on the table has small pits, the ground surface is good and flat so it must be in the casting.

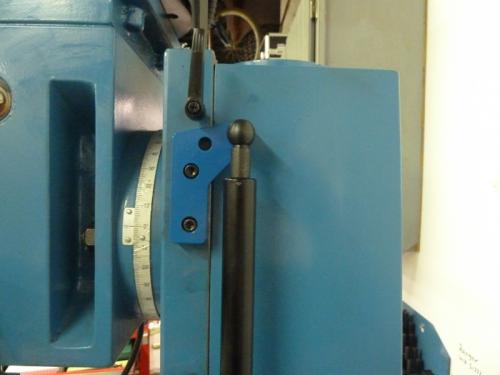

Once clean the next step was to install the right side gas spring. When drilling the first hole it was immediatly obvious that the casting was much harder than the old mill. It was dulling my bit after only 1 or 2 holes. The old mill drilled like butter.

Next I mounted the z-axis motor drive. No drama with the motor mount, all of the bolts lined up fine. More drilling and tapping holes for the control box and main box. The install went so much faster than the first time I did this on the old mill. No fab required.

I decided to install the x-axis drive next. I did mod the limit switch, routing the wire cord out the side of the box instead of the bottom. I also ground some of the casting to provide clearance for the gear that mounts to the mill. I am now fully powered up.

I hooked up the plug to confirm the motor runs and the spindle is turning the correct direction but I still plan on adding an e-switch before doing any actual machining. I also still need to mount the DRO scales which was the project I was working on when disaster struck

Dan

Collecting tools for 30 years.

Posts: 4,513

Threads: 139

Joined: Feb 2012

Location: Kempton Park. South Africa

Nicely done Dan

DaveH

Posts: 157

Threads: 18

Joined: Apr 2012

Location: Damascus, Or

Ya!. The old mill is finely delivered to the shipping company and should be on it's way back to Enco by tomorrow.

It will be a big weight off my shoulders when the $2k is credited back and off my card. So far the guys at Enco have been great to work with. I work at Crimson Trace where we make laser sights for hand guns and it turns out the guy I am working with at Enco (glenn) has one of our lasers on his gun. They love our products so I am going to send Glenn and his co-worker each a tee shirt as thanks for helping me out.

Collecting tools for 30 years.

Posts: 4,495

Threads: 187

Joined: Feb 2012

Location: Missouri, USA

Posts: 157

Threads: 18

Joined: Apr 2012

Location: Damascus, Or

Collecting tools for 30 years.

Posts: 4,683

Threads: 93

Joined: Feb 2012

Location: Perth, Australia

(11-27-2012, 07:13 PM)DanH Wrote: ...I am going to send Glenn and his co-worker each a tee shirt as thanks for helping me out.

Hey! We helped out too!!!!

Hunting American dentists since 2015.